Brass Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

Brass Wire Mesh

Brass wire mesh is braided with good ductility and malleability of brass wire, which contains 65% copper, 35% zinc, excellent filtration performance, bright color, smooth surface, common weaving methods for plain weave and twill weave, with good electrical and thermal conductivity, can withstand high temperature and heavy load, easy to cut, molding and welding, mainly used in pharmaceutical, metal powder filtration separation, ceramic printing, electromagnetic shielding and so on.

Brass Wire Mesh Specifications:

Guangtong Brass Wire Mesh of Specification Item Mesh (line/inch) Wire diameter (inch) Opening width (inches) Open area (%) Brass wire-1 2×2 0.0630 0.437 76.4 Brass wire-2 3×3 0.0630 0.270 65.6 Brass wire-3 4×4 0.0630 0.187 56.0 Brass wire-4 4×4 0.0470 0.203 65.9 Brass wire-5 6×6 0.0350 0.132 62.7 Brass wire-6 8×8 0.0280 0.097 60.2 Brass wire-7 10×10 0.0250 0.075 56.3 Brass wire-8 12×12 0.0230 0.060 51.8 Brass wire-9 14×14 0.0200 0.051 51.0 Brass wire-10 16×16 0.0180 0.045 50.7 Brass wire-11 18×18 0.0170 0.039 48.3 Brass wire-12 20×20 0.0160 0.034 46.2 Brass wire-13 24×24 0.0140 0.028 44.2 Brass wire-14 30×30 0.0130 0.020 37.1 Brass wire-15 40×40 0.0100 0.015 36.0 Brass wire-16 50×50 0.0090 0.011 30.3 Brass wire-17 60×60 0.0075 0.009 30.5 Brass wire-18 80×80 0.0055 0.007 31.4 Brass wire-19 100×100 0.0045 0.006 30.3 Brass Wire Mesh Features and Advantages

Corrosion resistance: brass wire mesh has good corrosion resistance, which can ensure that it is not easy to rust or corrosion in harsh environment;

Wear resistance: brass wire mesh has excellent wear resistance and can maintain good durability in long-term use;

Good tensile strength and extensibility: brass wire mesh has good tensile strength and extensibility, which can resist external force to a certain extent and is not easy to break;

Non-magnetic: brass wire mesh has high quality non-magnetic, ensuring that there will be no magnetic induction in the magnetic field and will not be affected by magnetic force.

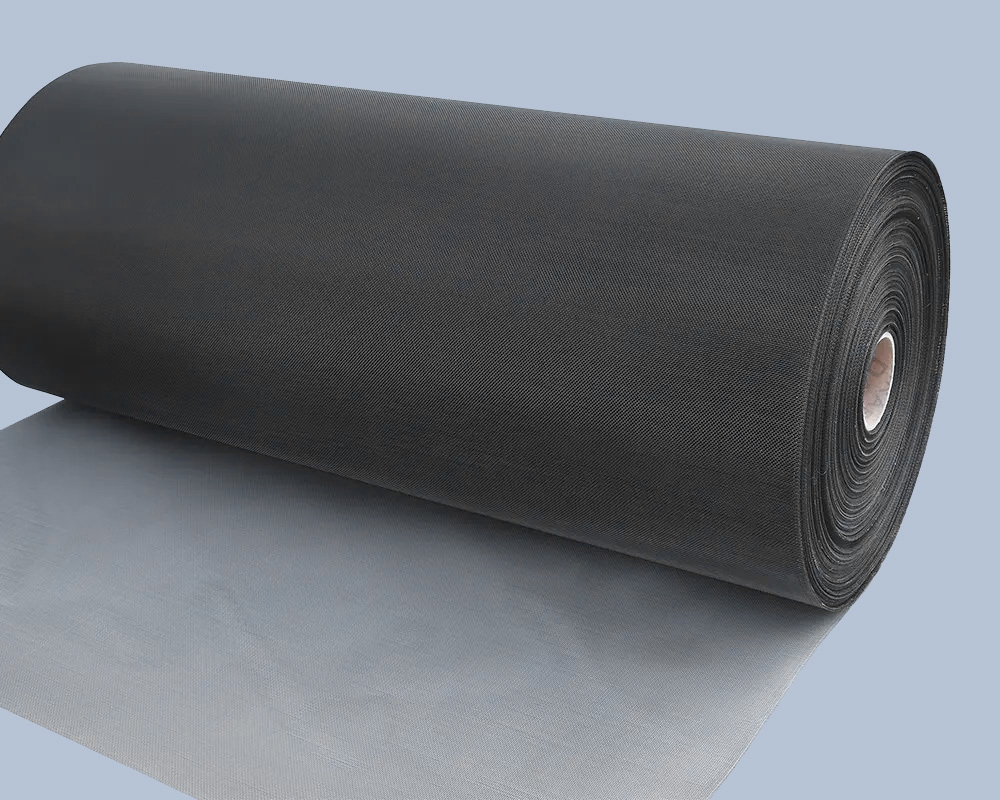

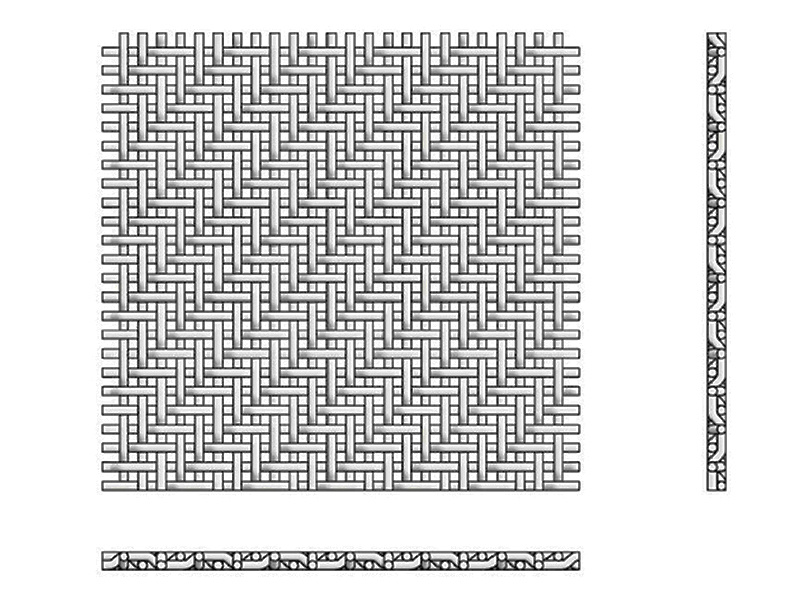

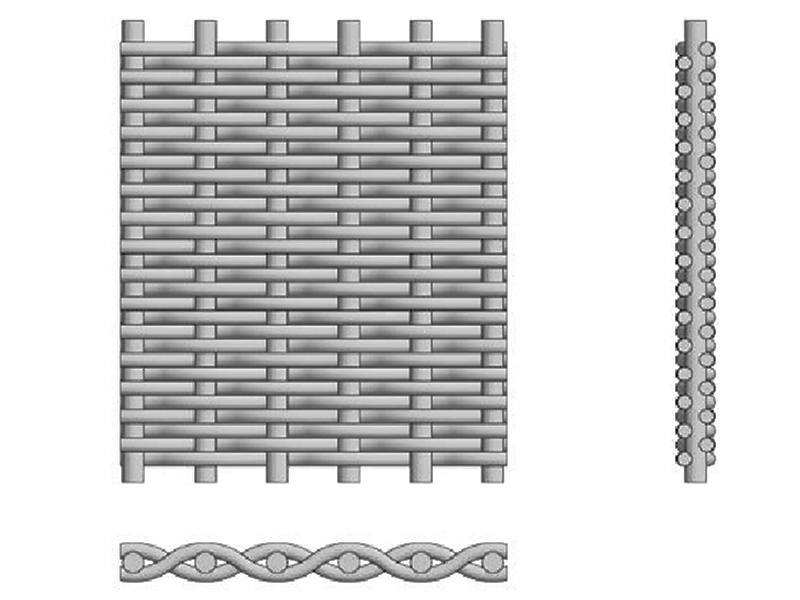

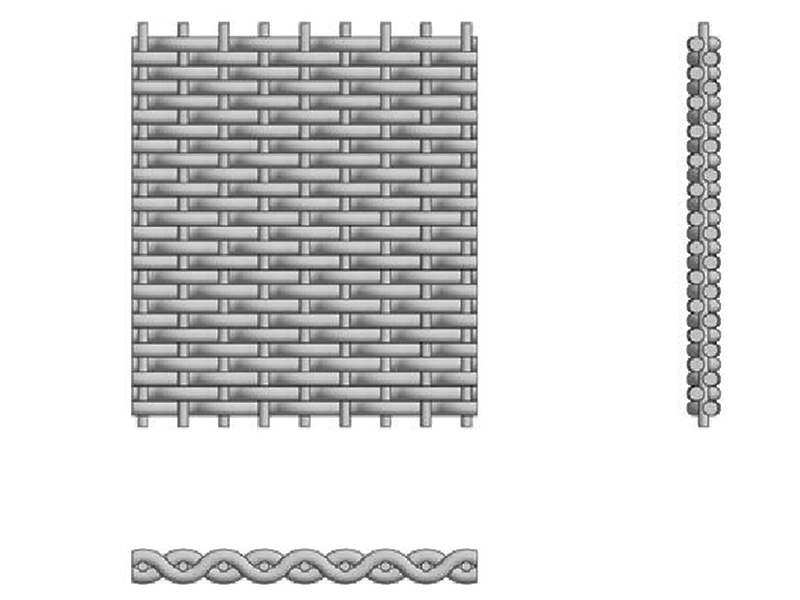

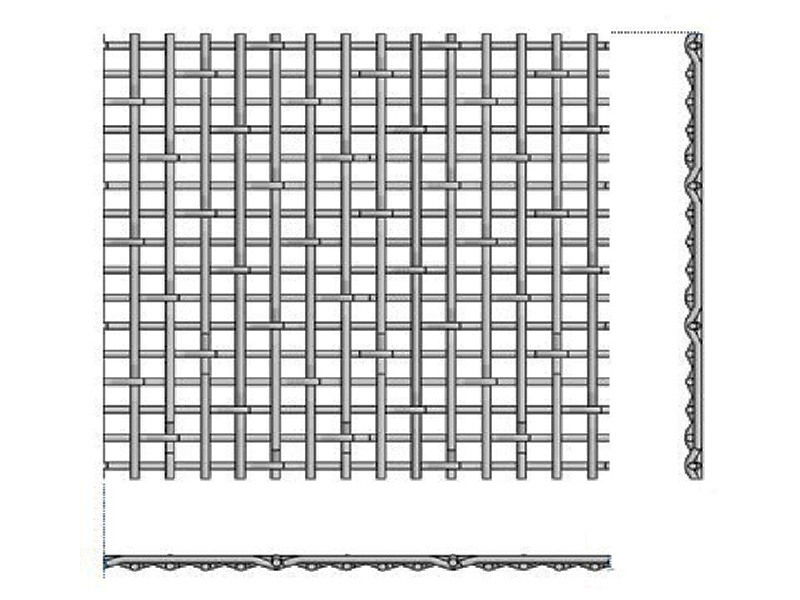

Brass Wire Mesh weaving method

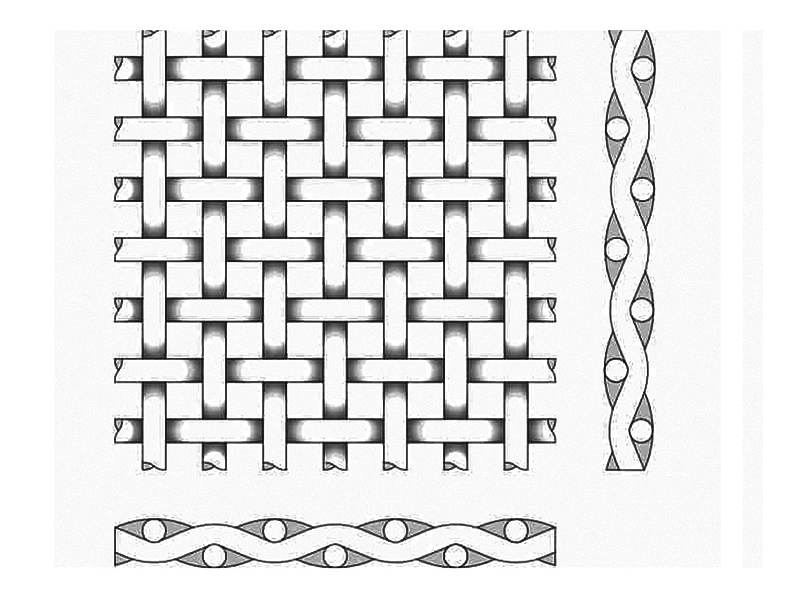

Plain weave

Each warp wire alternately passes through the top and bottom of each weft wire to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same.

Twill weave

Made by alternating each weft wire up and down two warp wire, interleaving on successive warp wire;

Dutch weaving

The warp wire adopts a thick mesh, the weft wire adopts a fine mesh, and the weft wire alternately passes up and down the two warp wire, forming a fine mesh in one direction, and a thick mesh in the other direction, forming a tight woven mesh with a conical or wedge opening;

Reverse dutch weave

Contrary to the layout of plain dutch weaving, the warp wire is made of fine mesh (mesh wire, woven wire mesh), the weft wire is made of thick mesh, and the number of wires is relatively small;

Five-Heddle weaving

Each warp wire alternately passes through the top and bottom of each weft wire to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same.

Herringbone weave

It is a special twill weave mesh, and the direction of the twill fabric is reversed every 20, 50, 100, 200, 500 mm according to the width and specific use, forming a skeleton shape similar to that of herring;

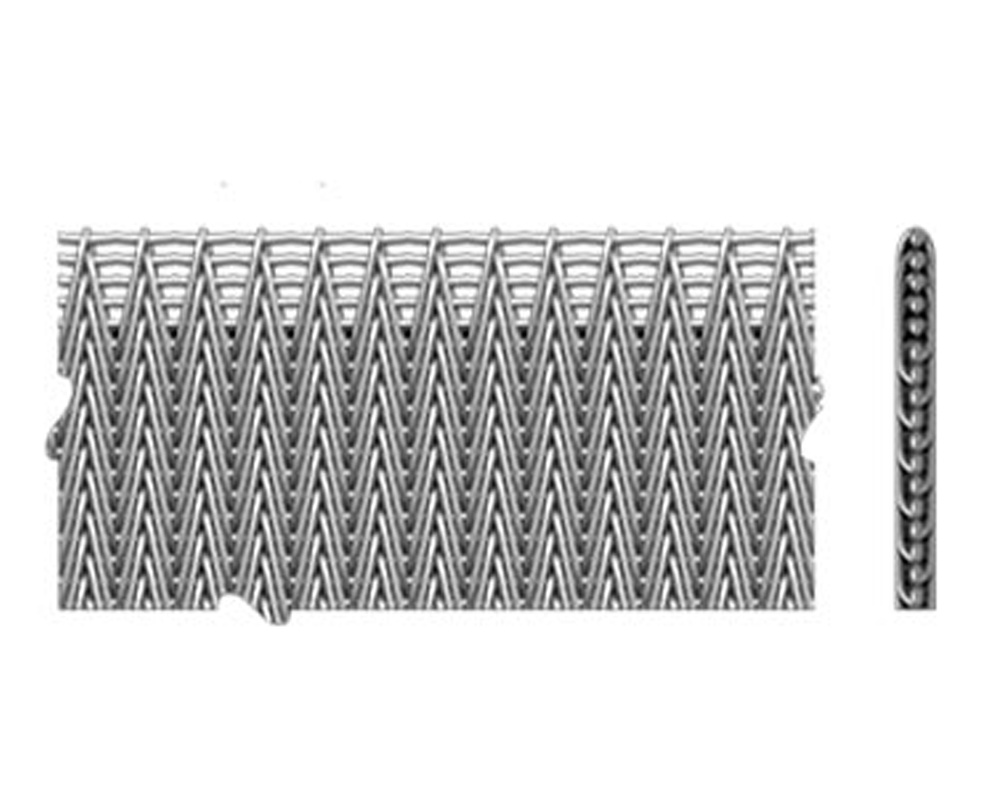

Crimped weave

Heavy metal mesh formed by interlocking or nesting of embossed wire mesh, which is bent at specified intervals during crimping to maintain a precise mesh structure.

According to customer needs, customized brass wire mesh with different weaving methods.

Brass Wire Mesh Inventory

Anping Guangtong Hardware Wire Mesh Co., Ltd. is a brass wire mesh manufacturer who is commited to professional design, research and development, production, with more than 20 years of experience in wire mesh production and processing field. In metal woven wire mesh’s field has an unshakable leading position, with a wide range of metal woven wire mesh inventory, it can more than 90% of the metal woven wire mesh manufacturers, in a number of inventory warehouses, there are 5000 different types of metal woven wire mesh. There are 3000-4000 types available for tailoring and same-day delivery.

(If we don't have what you need, or if you need a reliable long-term source throughout your supply chain, we can customize it as per your brass wire mesh specifications.)

Brass Wire Mesh Production Capacity

Anping Guangtong Hardware Wire Mesh Co., Ltd. covers an area of 40,000 square meters, with more than 400 weaving machines, an annual capacity of about 3600,000 square meters, has reached a strategic partnership with more than 60 countries in the world. We welcome your inquiries and send us sample requests.

Brass Wire Mesh Industry Certificate

The company has obtained and fully implemented ISO9001 Quality Management System Certification, ISO45001 Occupational Health And Safety Management System Certification, ISO14001 Environmental Management System Certification, IATF16949 Automotive Industry Quality Management System Certification, AEO customs certification and other related certifications.

Brass Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Brass wire mesh application

Can be used as a circuit, laboratory, computer room shielding screen, shielding efficiency calculator;

It can also be installed on the building for sound insulation or made of polymer extruder screen for polymer filtration.

Energy Sector

Chemical Processing

Beverage processing

Aviation

Automotive Processing

Aerospace

FAQ

How is the production process of brass wire mesh in your company? ls it quality guaranteed?

✔ Yes, the production process has a significant impact on the thickness and performance of the brass wire mesh, we will provide advanced technology, reliable quality brass wire mesh.

What kinds of woven brass wire mesh do you mainly provide?

✔ We can provide plain weave, twill weave, dutch weave, reverse dutch weave, five-heddle weave and herringbone weave for you to choose from.

Can you provide other brass wire mesh specifications not listed on the website?

✔ Yes, we can provide custom machining services and can provide other brass wire mesh specifications according to your needs.

What kind of brass wire mesh do you offer?

✔ We mainly supply H65 brass wire mesh, in addition to brass with different copper and zinc ratios.

Do you offer price discounts for large orders?

✔ Yes, you can contact one of our sales representatives to discuss this issue in detail.

Brass wire mesh is a versatile and durable material made from an alloy of copper and zinc. Its unique combination of strength, flexibility, and corrosion resistance makes it suitable for a wide range of applications across industrial, architectural, and decorative sectors. Known for its distinctive golden color and metallic luster, brass wire mesh offers both functional and aesthetic benefits, making it a preferred choice for filtration, screening, shielding, and decorative purposes.

Material Composition and Properties

Brass is an alloy primarily composed of copper (Cu) and zinc (Zn), with the proportions varying depending on the required mechanical and chemical properties. Common brass types used in wire mesh include C260 (70% Cu, 30% Zn) and C270 (67% Cu, 33% Zn). Copper provides excellent electrical and thermal conductivity, corrosion resistance, and antimicrobial properties, while zinc contributes to hardness, strength, and wear resistance.Brass wire mesh combines these properties, resulting in a material that is strong yet flexible, resistant to rust and corrosion, and able to maintain its structural integrity over time. Additionally, its metallic luster and warm golden hue make it aesthetically appealing, which is particularly valuable in architectural and decorative applications.

Manufacturing Process

Brass wire mesh is produced through several steps: drawing, annealing, and weaving.-

Wire Drawing – Brass rods are drawn through a series of dies to reduce diameter and achieve the desired wire thickness. This process enhances tensile strength and uniformity.

-

Annealing – The wires are heat-treated to increase ductility and reduce brittleness, ensuring flexibility during weaving.

-

Weaving – Wires are interlaced into mesh patterns using mechanical looms. Common weave types include plain weave, twill weave, and dutch weave. Plain weave is widely used for general applications, providing uniform openings and good strength. Twill weave offers diagonal patterns that increase durability and allow finer filtration. Dutch weave, with its tight warp and fine weft arrangement, is used for precise filtration and high-pressure applications.

The mesh can be supplied in rolls, sheets, or custom-cut sizes and fabricated into cylindrical, conical, or other shapes for specialized filtration elements or architectural panels.

Key Features and Advantages

-

Corrosion Resistance – Brass naturally resists corrosion, including exposure to water, air, and various chemicals, making it ideal for long-term use in indoor and outdoor environments.

-

Mechanical Strength – It provides good tensile strength and flexibility, maintaining its shape under stress while allowing some deformation without damage.

-

Thermal and Electrical Conductivity – Brass wire mesh efficiently conducts heat and electricity, making it suitable for electronic shielding, grounding applications, and heat dissipation.

-

Aesthetic Appeal – Its bright, golden metallic finish adds decorative value, making it suitable for architectural panels, facades, interior designs, and furniture.

-

Non-Magnetic – Brass is non-ferrous, preventing interference with magnetic fields, which is advantageous in electronic and industrial applications.

-

Ease of Fabrication – Brass wire mesh can be easily cut, bent, or shaped, allowing customization for specific designs and installation requirements.

Applications of Brass Wire Mesh

-

Filtration and Separation

-

Brass wire mesh is widely used in filtering liquids, gases, and powders.

-

Its corrosion resistance and ability to withstand repeated cleaning make it ideal for chemical, food, beverage, and water filtration systems.

-

Mesh can be fabricated into cylindrical filter elements, plates, or screens to meet specific filtration needs.

-

-

Screening and Sieving

-

Used in industries such as mining, pharmaceuticals, and food processing to separate particles by size.

-

Uniform pore sizes ensure consistent grading, while brass’s durability allows repeated use without wear.

-

-

Architectural and Decorative Applications

-

Its bright golden color and metallic sheen make brass wire mesh popular for decorative panels, facades, partitions, ceilings, and balustrades.

-

It is used both indoors and outdoors to create modern, luxurious, or traditional aesthetic designs.

-

Brass mesh can be powder-coated, polished, or treated for enhanced surface finish and durability.

-

-

Electrical and Electronic Applications

-

Brass wire mesh is used in electromagnetic interference (EMI) shielding, grounding screens, and electrical enclosures.

-

Its conductivity and non-magnetic properties make it suitable for protecting sensitive equipment from electrical noise.

-

-

Industrial Applications

-

Brass wire mesh is employed in chemical and petrochemical plants due to its resistance to corrosion from water, alkalis, and mild acids.

-

It is also used in heat exchangers, catalyst support screens, and separators in industrial processes.

-

-

Marine Applications

-

Brass wire mesh can withstand exposure to saltwater and humid coastal environments, making it suitable for marine screens, protective barriers, and decorative marine structures.

-

-

Acoustic and Vibration Applications

-

Due to its structure and material properties, brass wire mesh can be used for sound attenuation, vibration damping, and air flow management in HVAC systems and mechanical equipment.

-

-

Antimicrobial Applications

-

Copper in brass exhibits natural antimicrobial properties, making brass wire mesh suitable for applications in medical, food processing, and water treatment where hygiene is critical.

-

Customization and Fabrication

Brass wire mesh can be tailored to meet specific needs:-

Mesh Count and Aperture Size – Fine mesh for microfiltration or decorative applications, coarse mesh for structural or screening purposes.

-

Wire Diameter – Thicker wires for strength and durability, thinner wires for precise filtration.

-

Weave Type – Plain, twill, or dutch weave depending on mechanical and filtration requirements.

-

Shape and Form – Rolls, sheets, cylinders, cones, or custom designs.

-

Surface Treatment – Polishing, coating, or plating to enhance corrosion resistance, durability, or aesthetics.

Maintenance and Longevity

Brass wire mesh is relatively low-maintenance. Routine cleaning with water, mild detergents, or non-abrasive brushes maintains appearance and performance. In filtration applications, periodic backwashing or ultrasonic cleaning can restore efficiency. Its corrosion resistance and mechanical durability ensure a long service life, often exceeding decades with proper care.Environmental Considerations

-

Brass is recyclable, contributing to sustainable use and reduced material waste.

-

Its long lifespan and low replacement frequency minimize environmental impact.

-

Non-toxic and safe for use in food, water, and medical applications.

Advantages of Brass Wire Mesh

-

Excellent corrosion and wear resistance.

-

High strength with flexibility for diverse applications.

-

Attractive metallic finish for decorative and architectural use.

-

Conductive and non-magnetic properties suitable for electronics.

-

Easy to fabricate, shape, and customize.

-

Durable and low-maintenance, ensuring long-term performance.

Conclusion

Brass wire mesh is a highly versatile and functional material that combines strength, corrosion resistance, conductivity, and aesthetic appeal. Its wide range of applications spans industrial filtration, screening, chemical processing, marine structures, architectural and decorative designs, and electronic shielding. The combination of durability, low maintenance, and visual attractiveness makes brass wire mesh a preferred choice across industries worldwide. Its adaptability allows engineers, designers, and architects to integrate it into functional and aesthetic projects while benefiting from its inherent mechanical and chemical properties -

Brass Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products