Epoxy Coated Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

- 产品描述

-

Epoxy Coated Wire Mesh

Epoxy coated wire mesh consists of a single wire mesh woven into a mesh pattern, which is then coated with epoxy resin to provide corrosion resistance, and the diameter, length and pattern of the single wire mesh may vary depending on the application. Common materials are stainless steel, low carbon steel, aluminum alloy, epoxy powder, we can provide the color according to your requirements, usually the color of the epoxy coating is black, black epoxy coated wire mesh consists of different external coating compounds: epoxy resin and polyamine hardener. When the epoxy coating is fully cured, the resulting product is a durable, rigid plastic coating that is usually suitable for ordinary steel. Epoxy coated wire mesh is an important material in construction engineering, they can provide high load carrying capacity and strength for concrete or ground and various basic structures.

Please refer to the information below, our mesh experts can help you determine the right mesh for your application.

Epoxy Coated Wire Mesh Specifications

Epoxy Coated Remesh Sheets STYLE W×L PACKAGED(BUNDLES) STD.T/L QTY. 6X6-W1.4/W1.4 8'×20' 100 Sheets 1400 6X6-W1.4/W1.4 8'x15' 100 Sheets 2000 6X6-W1.4/W1.4 8'x12'6" 100 Sheets 2400 6X6-W1.4/W1.4 5'x10' 100 Sheets 3500 6X6-D2.1/D2.1 8′×20′ 50 Sheets 1050 6X6-D2.1/D2.1 8'x15' 50 Sheets 1400 6X6-D2.1/D2.1 8'x12'6" 50 Sheets 1700 6X6-D2.1/D2.1 5'x10′ 100 Sheets 3000 6X6-D2.9/D2.9 8'×20' 50 Sheets 750 6X6-D2.9/D2.9 8'x15' 50 Sheets 1000 6X6-D2.9/D2.9 8′×12'6" 50 Sheets 1200 6X6-D2.9/D2.9 5'x10' 100 Sheets 2000 6X6-D4/D4 8'×20' 50 Sheets 525 6X6-D4/D4 8'x15' 50 Sheets 700 6X6-D4/D4 8'×12'6" 50 Sheets 850 6X6-D4/D4 5'x10' 50 Sheets 1500 4X4-D2.9/D2.9 8'×20' 50 Sheets 500 4X4-D2.9/D2.9 8'x15′ 50 Sheets 650 4X4-D2.9/D2.9 8'x12'6" 50 Sheets 800 4X4-D2.9/D2.9 5'x10′ 100 Sheets 1600 4X4-D4/D4 8'×20' 25 Sheets 350 4X4-D4/D4 8'x15' 25 Sheets 475 4X4-D4/D4 8'×12'6" 50 Sheets 550 4X4-D4/D4 5′×10' 50 Sheets 1150 Rolls

STYLE W×L PACKAGED(BUNDLES) STD.T/L QTY. 6X6-W1.4/W1.4 5'×150' 18 Rolls 324 6X6-W1.4/W1.4 6'×150' 17 Rolls 272 6X6-W1.4/W1.4 5'×200' 15 or 12 &7 Rolls 240 6X6-D2.1/D2.1 5'×150' 15 Rolls 225 6X6-D2.9/D2.9 5'×150' 12 &8 Rolls 160 Epoxy Coated Wire Mesh Features and Advantages

Strong adhesion

The epoxy coating of epoxy coated wire mesh has excellent adhesion to metal, cement, glass fiber reinforced plastic and other materials, which can ensure that the coating is firmly attached to the substrate and is not easy to fall of;

Wear and corrosion resistant environment

Epoxy coated wire mesh has good wear resistance and corrosion resistance, can resist the erosion of chemical substances, suitable for a variety of harsh;

Good stability

Epoxy coated wire mesh paint film is tough, impact resistance, wear resistance, toughness and bending resistance, which can provide good protection effect for the screen and improve the service life;

Easy to use

Epoxy coated wire mesh coating can be cured into film at normal temperature, which is not affected by the site environment, easy to use and simple to operate.

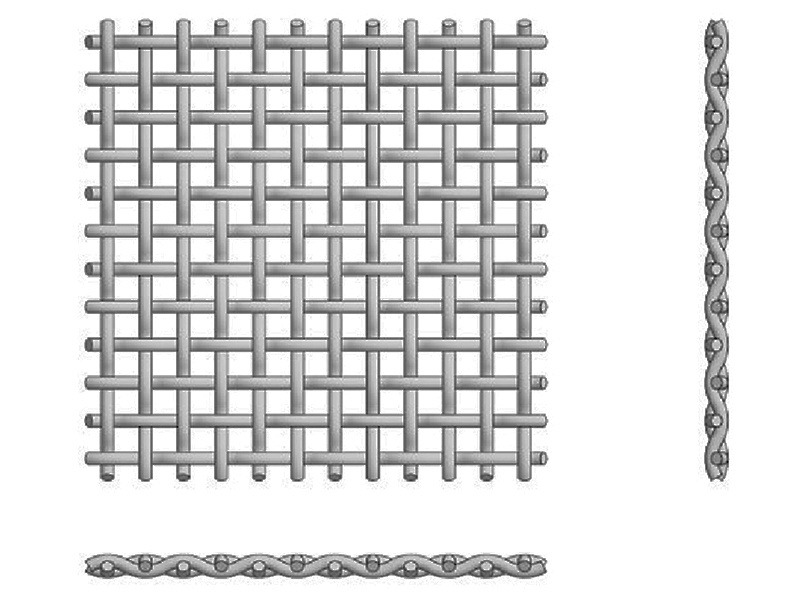

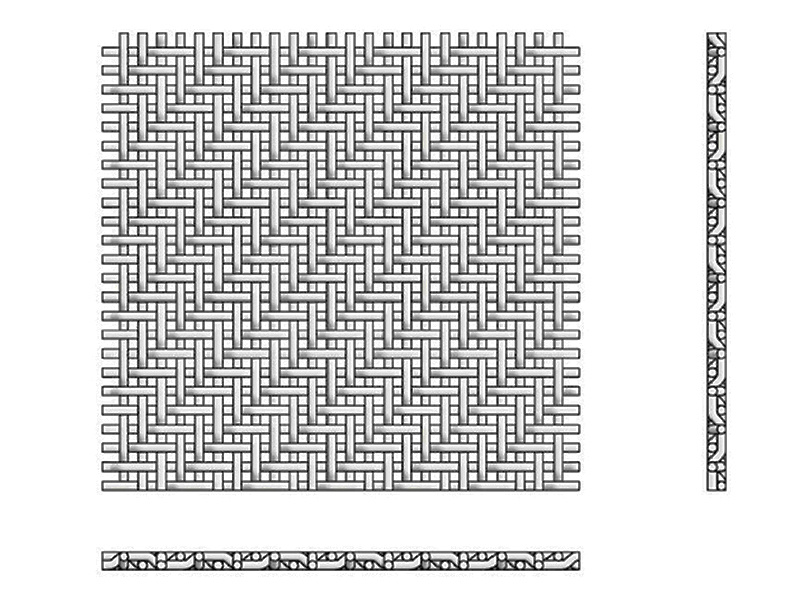

Epoxy Coated Wire Mesh weaving method

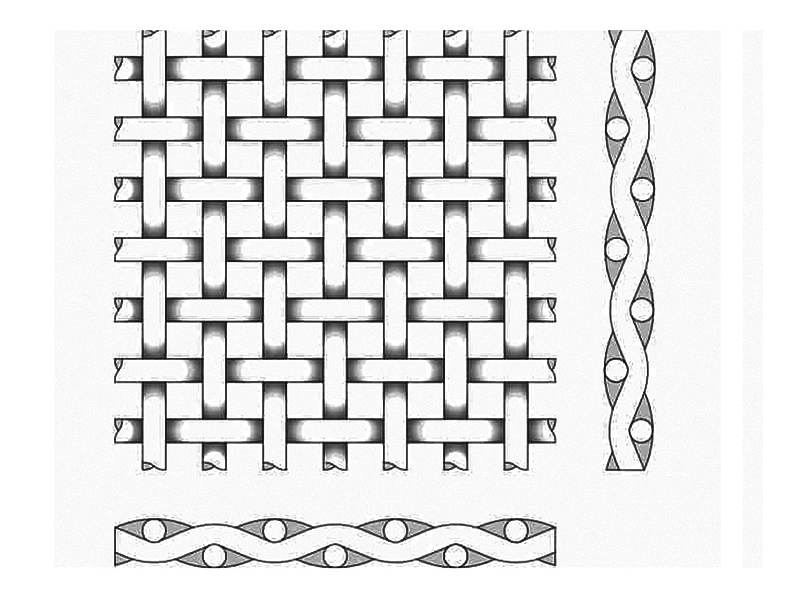

Plain weave

Each warp wire alternately passes through the top and bottom of each weft wire to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same.

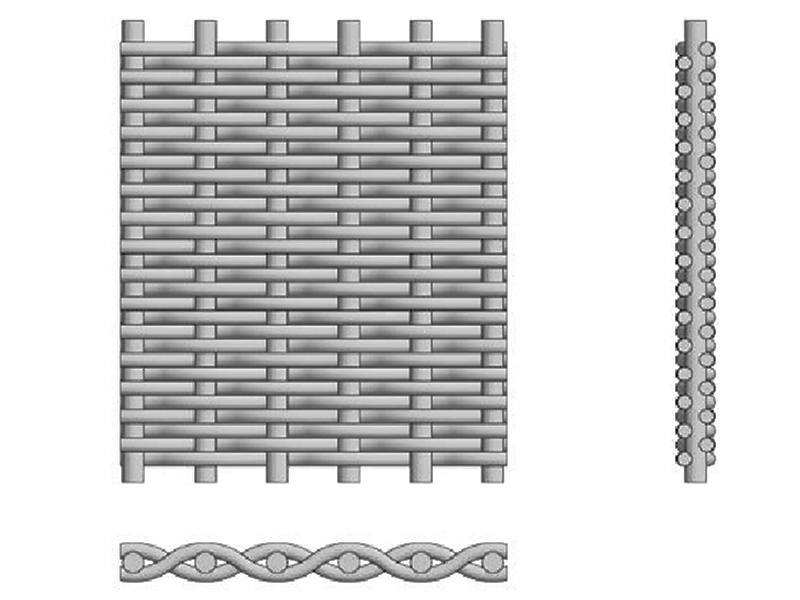

Twill weave

Made by alternating each weft wire up and down two warp wire, interleaving on successive warp wire;

Dutch weaving

The warp wire adopts a thick mesh, the weft wire adopts a fine mesh, and the weft wire alternately passes up and down the two warp wire, forming a fine mesh in one direction, and a thick mesh in the other direction, forming a tight woven mesh with a conical or wedge opening;

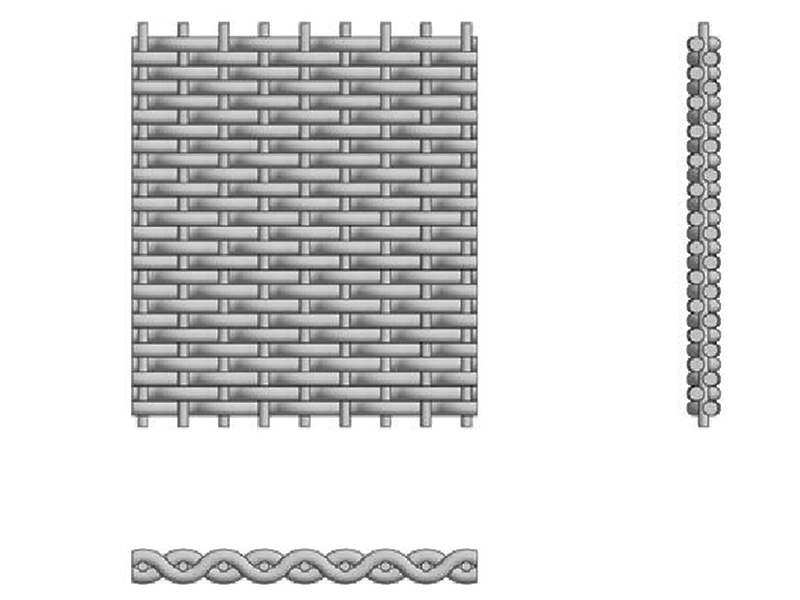

Reverse dutch weave

Contrary to the layout of plain dutch weaving, the warp wire is made of fine mesh (mesh wire, woven wire mesh), the weft wire is made of thick mesh, and the number of wires is relatively small;

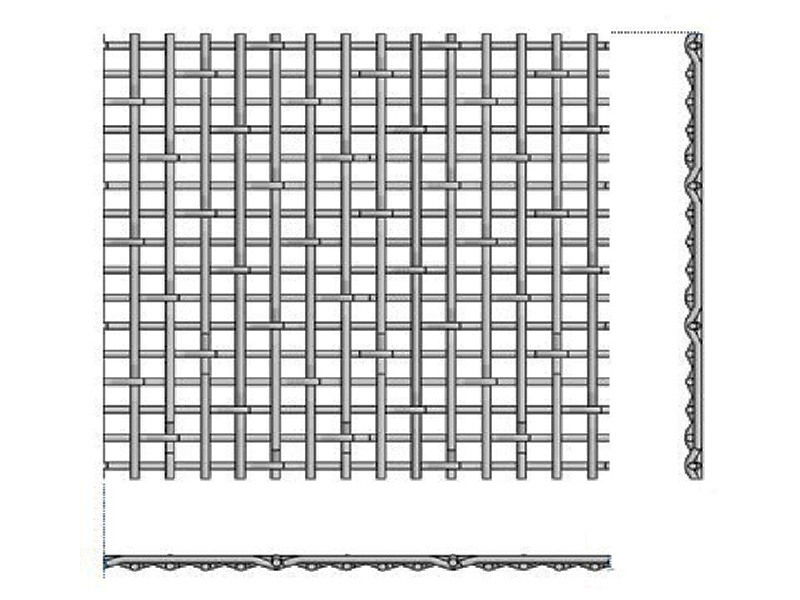

Five-Heddle weaving

Each warp wire alternately passes through the top and bottom of each weft wire to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same.

Herringbone weave

It is a special twill weave mesh, and the direction of the twill fabric is reversed every 20, 50, 100, 200, 500 mm according to the width and specific use, forming a skeleton shape similar to that of herring;

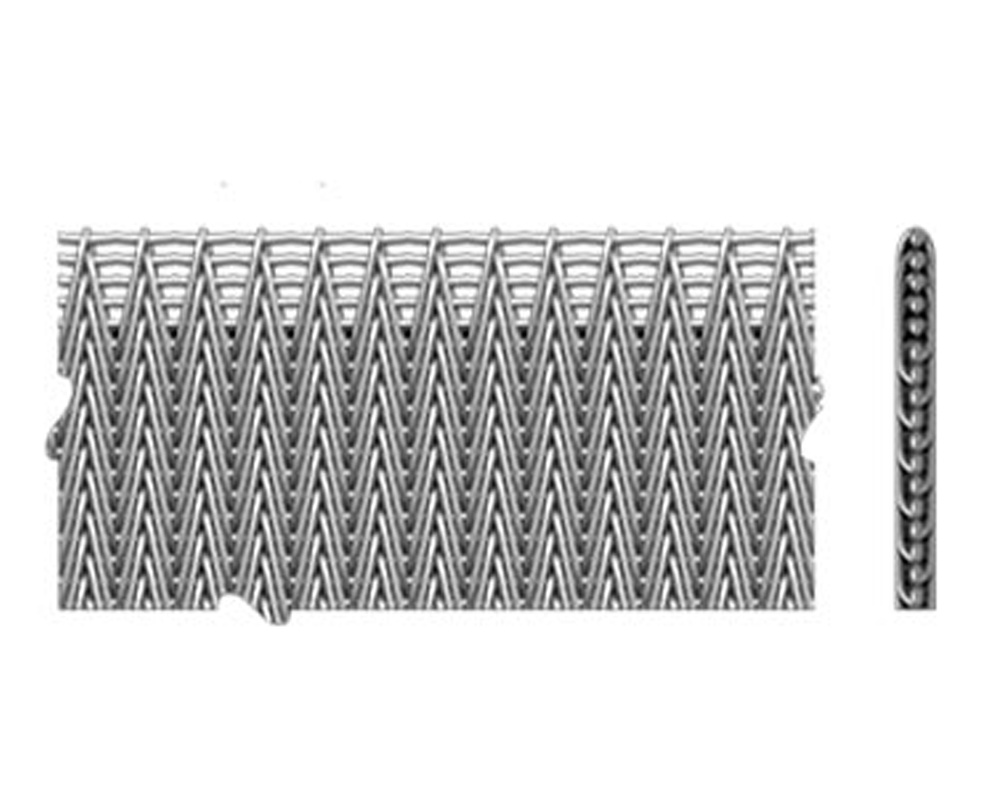

Crimped weave

Heavy metal mesh formed by interlocking or nesting of embossed wire mesh, which is bent at specified intervals during crimping to maintain a precise mesh structure.

According to customer needs, customized epoxy coated wire mesh with different weaving methods.

Epoxy Coated Wire Mesh Inventory

Anping Guangtong Hardware Wire Mesh Co., Ltd. is a epoxy coated wire mesh manufacturer who is commited to professional design, research and development, production, with more than 20 years of experience in wire mesh production and processing field. In metal woven wire mesh’s field has an unshakable leading position, with a wide range of metal woven wire mesh inventory, it can more than 90% of the metal woven wire mesh manufacturers, in a number of inventory warehouses, there are 5000 different types of metal woven wire mesh. There are 3000-4000 types available for tailoring and same-day delivery.

(If we don't have what you need, or if you need a reliable long-term source throughout your supply chain, we can customize it as per your epoxy coated wire mesh specifications.)

Epoxy Coated Wire Mesh Production Capacity

Anping Guangtong Hardware Wire Mesh Co., Ltd. covers an area of 40,000 square meters, with more than 400 weaving machines, an annual capacity of about 3600,000 square meters, has reached a strategic partnership with more than 60 countries in the world. We welcome your inquiries and send us sample requests.

Epoxy Coated Wire Mesh Industry Certificate

The company has obtained and fully implemented ISO9001 Quality Management System Certification, ISO45001 Occupational Health And Safety Management System Certification, ISO14001 Environmental Management System Certification, IATF16949 Automotive Industry Quality Management System Certification, AEO customs certification and other related certifications.

Epoxy Coated Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Epoxy Coated Wire Mesh Application

It is commonly used in the aerospace, automotive, and energy sectors, as well as in chemical processes such as the production of adhesives, resins, and coatings. It can also be used in filtration and screening applications in the food and beverage industry.

Food Processing

Energy Sector

Chemical Processing

Aviation

Automotive Processing

Aerospace

FAQ

Do you guarantee the quality of your epoxy coated wire mesh?

✔ Yes, we have a professional epoxy coated wire mesh production line to ensure that it is produced in a dry and suitable temperature environment.

Can you guarantee that your epoxy coated wire mesh will be delivered safely and reliably?

✔ Yes, we always use high quality export packaging. Of course, it can also be packed according to your requirements, but this may incur additional costs.

Can you provide other epoxy coated wire mesh specifications not listed on the website?

✔ Yes, we can provide custom machining services and can provide other epoxy coated wire mesh specifications according to your needs.

What colors and patterns do you offer for epoxy coated wire mesh?

✔ Usually the color of epoxy coated wire mesh is black, we can provide colors and patterns according to your requirements.

What are the usual materials of your epoxy coated wire mesh?

✔ Our common materials are stainless steel, low carbon steel, aluminum alloy, epoxy powder, etc. Other materials can be customized according to your needs.

Epoxy coated wire mesh is a durable and versatile metal mesh product widely used in industrial, commercial, and architectural applications. This mesh consists of a base metal, typically steel, stainless steel, or aluminum, coated with a layer of epoxy resin. The epoxy coating enhances the mesh’s resistance to corrosion, chemical attack, and environmental wear while maintaining mechanical strength and flexibility. Its combination of protective performance and aesthetic appeal makes it ideal for applications ranging from filtration and screening to fencing and decorative architectural elements.

Material Composition and Properties

The base metal of epoxy coated wire mesh can be mild steel, stainless steel, or aluminum. Each base material offers specific advantages:

-

Steel provides strength and rigidity.

-

Stainless steel adds corrosion resistance and long-term durability.

-

Aluminum offers lightweight properties and natural corrosion resistance.

The epoxy coating is a polymer layer that adheres to the metal surface, creating a smooth, non-porous, and chemically resistant barrier. The coating is generally applied through dipping, spraying, or electrostatic deposition, followed by curing at controlled temperatures to ensure adhesion and uniform thickness. Thickness, color, and finish of the epoxy can be customized according to the application requirements.

Key Features

-

Enhanced Corrosion Resistance – Epoxy coated wire mesh protects the base metal from rust, oxidation, and chemical exposure. It is suitable for outdoor, humid, or chemically aggressive environments.

-

Mechanical Strength and Durability – While providing a protective layer, the epoxy does not compromise the mechanical performance of the underlying mesh. The mesh retains its tensile strength, rigidity, and load-bearing capacity.

-

Chemical Resistance – Epoxy coatings resist acids, alkalis, salts, and solvents, making the mesh suitable for chemical plants, water treatment facilities, and filtration systems.

-

Aesthetic Appeal – The coating can be produced in various colors, finishes, and textures, providing a visually appealing surface suitable for architectural or decorative applications.

-

Low Maintenance – The smooth, non-porous surface resists dirt, debris, and fouling, making cleaning and maintenance easier.

-

Flexibility and Adaptability – Epoxy coated mesh maintains flexibility while resisting cracking, making it suitable for curved or complex installations.

Manufacturing Process

The production of epoxy coated wire mesh typically follows these steps:

-

Preparation of the Base Metal – The wire is cleaned and degreased to remove rust, oil, and impurities.

-

Application of Epoxy Coating – Methods include:

-

Dip Coating: Immersing the mesh in epoxy resin for complete coverage.

-

Spray Coating: Using a spray to evenly coat the mesh.

-

Electrostatic Coating: Applying a charged epoxy powder or liquid that adheres uniformly to the mesh surface.

-

-

Curing – The coated mesh is heated at controlled temperatures to solidify the epoxy, ensuring adhesion and durability.

Weave Types and Design

Epoxy coated wire mesh can be produced in various weave types, depending on its intended application:

-

Plain Weave – Simple over-and-under pattern, suitable for general applications and moderate filtration.

-

Twill Weave – Diagonal pattern allowing tighter openings, increased strength, and resistance to wear.

-

Dutch Weave – Dense warp and fine weft wires, ideal for precise filtration under high pressure.

Applications

-

Filtration and Separation

-

Epoxy coated wire mesh is widely used in liquid, gas, and powder filtration.

-

Its chemical and corrosion resistance ensures long-term performance in water treatment plants, chemical processing, and food and beverage industries.

-

Mesh can be fabricated into cylindrical filters, plates, or panels for specific filtration requirements.

-

-

Screening and Sieving

-

Used for particle separation and grading in mining, pharmaceuticals, and industrial processes.

-

Uniform mesh size ensures accurate and consistent separation.

-

-

Fencing and Protective Barriers

-

Provides durable, corrosion-resistant fencing for residential, commercial, and industrial properties.

-

Used as machine guards, protective enclosures, and safety barriers.

-

-

Architectural and Decorative Applications

-

Epoxy coated mesh enhances the aesthetic appeal of building facades, partitions, ceilings, and decorative panels.

-

Colored or textured coatings allow for customization according to design preferences.

-

It maintains durability while offering modern, clean aesthetics for both indoor and outdoor environments.

-

-

Industrial Applications

-

Applied in chemical plants, oil refineries, and petrochemical facilities due to chemical resistance.

-

Used in ventilation panels, heat exchangers, and screens requiring mechanical strength and resistance to environmental exposure.

-

-

Marine and Outdoor Applications

-

Epoxy coating protects against saltwater corrosion, moisture, and UV exposure.

-

Suitable for docks, jetties, outdoor walkways, and coastal structures.

-

-

Electronics and Electrical Applications

-

Non-conductive epoxy coating provides insulation while maintaining mechanical performance.

-

Used in protective enclosures, EMI shielding, and ventilation panels in electrical equipment.

-

Advantages of Epoxy Coated Wire Mesh

-

Extended lifespan due to corrosion protection.

-

High strength and mechanical stability.

-

Resistance to chemicals, moisture, and UV exposure.

-

Customizable colors, textures, and thicknesses.

-

Aesthetic appeal for architectural and decorative applications.

-

Low maintenance and easy cleaning.

-

Versatile applications across multiple industries.

Maintenance and Longevity

Epoxy coated wire mesh requires minimal maintenance. Its smooth and non-porous surface prevents dirt and debris accumulation. Routine cleaning with water or mild detergents is sufficient to maintain appearance and performance. For industrial or filtration applications, ultrasonic cleaning, chemical cleaning, or backwashing may be employed without damaging the epoxy coating. Proper care ensures a service life of decades, even in harsh environments.

Environmental and Sustainability Considerations

-

Epoxy coatings can be formulated with environmentally friendly resins, reducing ecological impact.

-

Long service life decreases the need for frequent replacement and reduces material waste.

-

Recyclable base metals, such as steel or aluminum, further enhance sustainability.

Customization Options

-

Mesh Size and Wire Diameter – Fine or coarse mesh depending on application.

-

Weave Type – Plain, twill, or dutch weave for filtration or structural requirements.

-

Shape and Form – Sheets, rolls, cylinders, or custom-designed panels.

-

Coating Color and Finish – Various colors, textures, and thicknesses.

-

Base Material Selection – Steel, stainless steel, or aluminum according to strength and corrosion requirements.

Conclusion

Epoxy coated wire mesh combines durability, corrosion resistance, chemical stability, and aesthetic versatility. Its protective coating extends the lifespan of the underlying metal while maintaining mechanical strength, flexibility, and adaptability. The mesh is widely used for filtration, screening, protective fencing, industrial applications, marine environments, and architectural or decorative elements. Its customizable properties, low maintenance, and long service life make epoxy coated wire mesh a reliable and versatile solution across numerous industries worldwide.

-

Epoxy Coated Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products