Stainless Steel Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

Stainless Steel Wire Mesh

Stainless Steel Wire Mesh includes 304, 304L, 316, 316L, 310, 310S, 314, 321 and other stainless steel materials with rust, corrosion resistance, grinding resistance, acid and alkali resistance, high strength, durable and other characteristics, widely used in liquid, gas, solid filtration and other occasions, we offer a wide range of weaves in Plain Weave, Twill Weave, Dutch Weave, Reverse Dutch Weave, Five-Heddle Weave, Crimped Weave and other weaves. We offer a wide range of shapes, surface treatments, and special alloy choices. In order to meet the needs of various industries for filtration rate or open area, the length of the cutting size can be provided according to the quantity.

Please refer to the information below, our mesh experts can help you determine the right mesh for your application.

Stainless Steel Wire Mesh Specifications

Specification of Stainless Steel Wire Mesh tem Mesh/Inch Wire Diameter Aperture Open Area Weight

(LB/100 Square Foot)inch mm inch mm % SS-1 1×1 0.0800 2.0300 0.9200 23.3700 84.60 41.10 SS-2 2×2 0.0630 1.6000 0.4370 11.1000 76.40 51.20 SS-3 3×3 0.0540 1.3700 0.2790 7.0900 70.10 56.70 SS-4 4×4 0.0630 1.6000 0.1870 4.7500 56.00 104.80 SS-5 4×4 0.0470 1.1900 0.2030 5.1600 65.90 57.60 SS-6 5×5 0.0410 1.0400 0.1590 4.0400 63.20 54.90 SS-7 6×6 0.0350 0.8900 0.1320 3.3500 62.70 48.10 SS-8 8×8 0.0280 0.7100 0.0970 2.4600 50.20 41.10 SS-9 10×10 0.0250 0.6400 0.0750 1.9100 56.30 41.20 SS-10 10×10 0.0200 0.5100 0.0800 2.0300 64.00 26.10 SS-11 12×12 0.0230 0.5840 0.0600 1.5200 51.80 42.20 SS-12 12×12 0.0200 0.5080 0.0630 1.6000 57.20 31.60 SS-13 14×14 0.0230 0.5840 0.0480 1.2200 45.20 49.80 SS-14 14×14 0.0200 0.5080 0.0510 1.3000 51.00 37.20 SS-15 16×16 0.0180 0.4570 0.0445 1.1300 50.70 34.50 SS-16 18×18 0.0170 0.4320 0.0386 0.9800 48.30 34.80 SS-17 20×20 0.0200 0.5080 0.0300 0.7600 36.00 55.20 SS-18 20×20 0.0160 0.4060 0.0340 0.8600 46.20 34.40 SS-19 24×24 0.0140 0.3560 0.0277 0.7000 44.20 31.80 SS-20 30×30 0.0130 0.3300 0.0203 0.5200 37.10 34.80 SS-21 30×30 0.0120 0.3050 0.0213 0.5400 40.80 29.40 SS-22 30×30 0.0090 0.2290 0.0243 0.6200 53.10 16.10 SS-23 35×35 0.0110 0.2790 0.0176 0.4500 37.90 29.00 SS-24 40×40 0.0100 0.2540 0.0150 0.3800 36.00 27.60 SS-25 50×50 0.0090 0.2290 0.0110 0.2800 30.30 28.40 SS-26 50×50 0.0080 0.2030 0.0120 0.3100 36.00 22.10 SS-27 60×60 0.0075 0.1910 0.0092 0.2300 30.50 23.70 SS-28 60×60 0.0070 0.1780 0.0097 0.2500 33.90 20.40 SS-29 70×70 0.0065 0.1650 0.0078 0.2000 29.80 20.80 SS-30 80×80 0.0065 0.1650 0.0060 0.1500 23.00 23.20 SS-31 80×80 0.0055 0.1400 0.0070 0.1800 31.40 16.90 SS-32 90×90 0.0050 0.1270 0.0061 0.1600 30.10 15.80 SS-33 100×100 0.0045 0.1140 0.0055 0.1400 30.30 14.20 SS-34 100×100 0.0040 0.1020 0.0060 0.1500 36.00 11.00 SS-35 100×100 0.0035 0.0890 0.0065 0.1700 42.30 8.30 SS-36 110×110 0.0040 0.1016 0.0051 0.1295 30.70 12.40 SS-37 120×120 0.0037 0.0940 0.0064 0.1168 30.70 11.60 SS-38 150×150 0.0026 0.0660 0.0041 0.1041 37.40 7.10 SS-39 160×160 0.0025 0.0635 0.0038 0.0965 36.40 5.94 SS-40 180×180 0.0023 0.0584 0.0033 0.0838 34.70 6.70 SS-41 200×200 0.0021 0.0533 0.0029 0.0737 33.60 6.20 SS-42 250×250 0.0016 0.0406 0.0024 0.0610 36.00 4.40 SS-43 270×270 0.0016 0.0406 0.0021 0.0533 32.20 4.70 SS-44 300×300 0.0051 0.0381 0.0018 0.0457 29.70 3.04 SS-45 325×325 0.0014 0.0356 0.0017 0.0432 30.00 4.40 SS-46 400×400 0.0010 0.0254 0.0015 0.3700 36.00 3.30 SS-47 500×500 0.0010 0.0254 0.0010 0.0254 25.00 3.80 SS-48 635×635 0.0008 0.0203 0.0008 0.0203 25.00 2.63 Stainless Steel Wire Mesh Features and Advantages

Corrosion resistance

Stainless steel material has strong corrosion resistance, can adapt to various corrosive environments, can ensure the service life of the screen and stainless steel filter element;.

Abrasion resistance

Stainless steel woven mesh has excellent anti-wear performance, which can ensure that the screen and stainless steel filter element are used for a long time in harsh environments and are not easy to wear;

Easy to clean

Stainless steel surface smooth, not easy to attach impurities, easy to clean and maintain, can reduce operating costs;

Strong and durable

Stainless steel woven mesh has high strength, strong tensile ability, can withstand high load, high temperature resistance, can ensure that the screen and stainless steel filter element in high temperature environment to maintain stability and durability.

Stainless Steel Wire Mesh weaving method

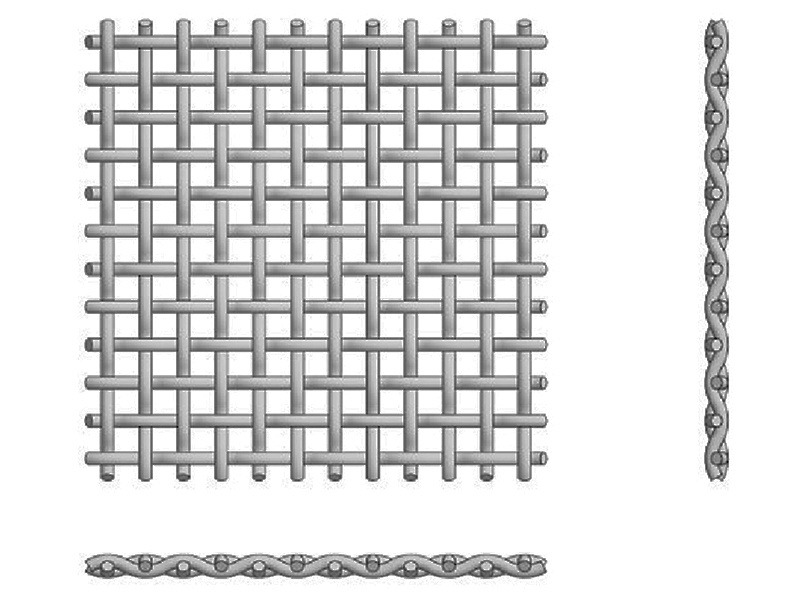

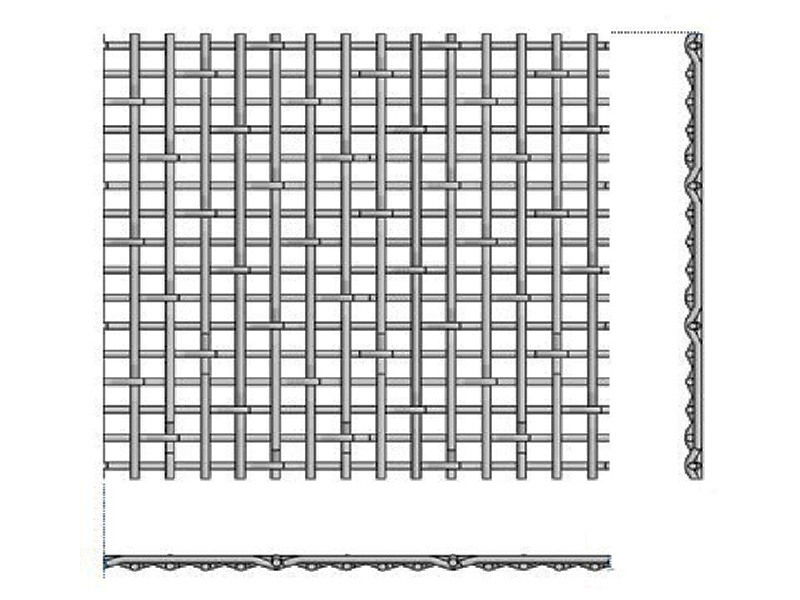

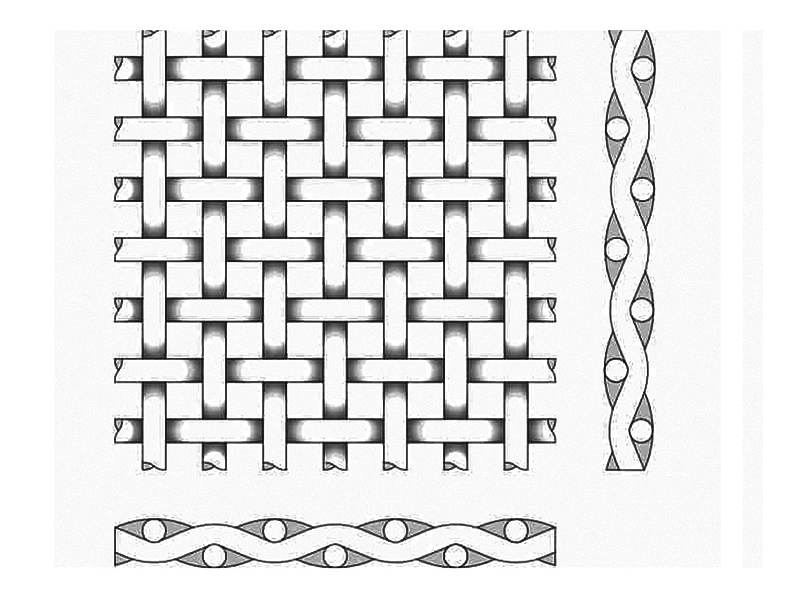

Plain weave

Each warp wire, weft wire alternately passes through the top and bottom of each to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same.

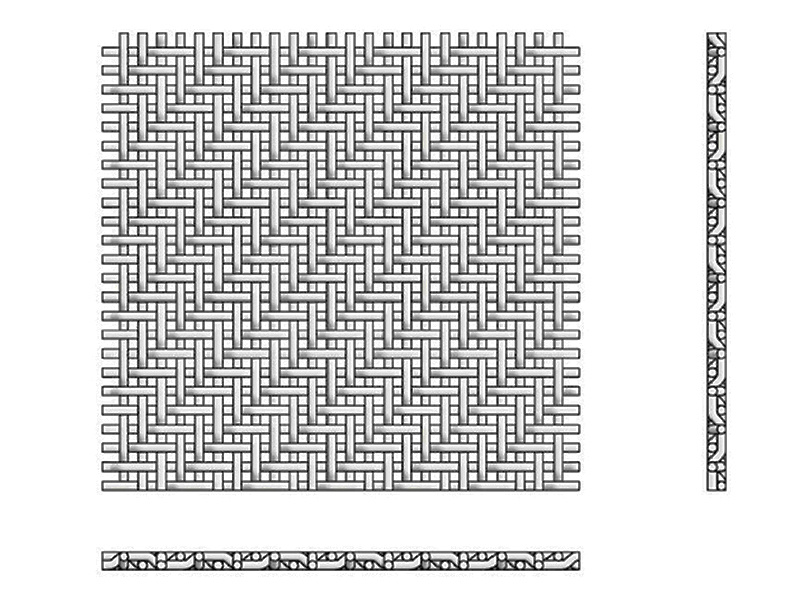

Twill weave

Made by alternating each weft wire up and down two warp wire, interleaving on successive warp wire;

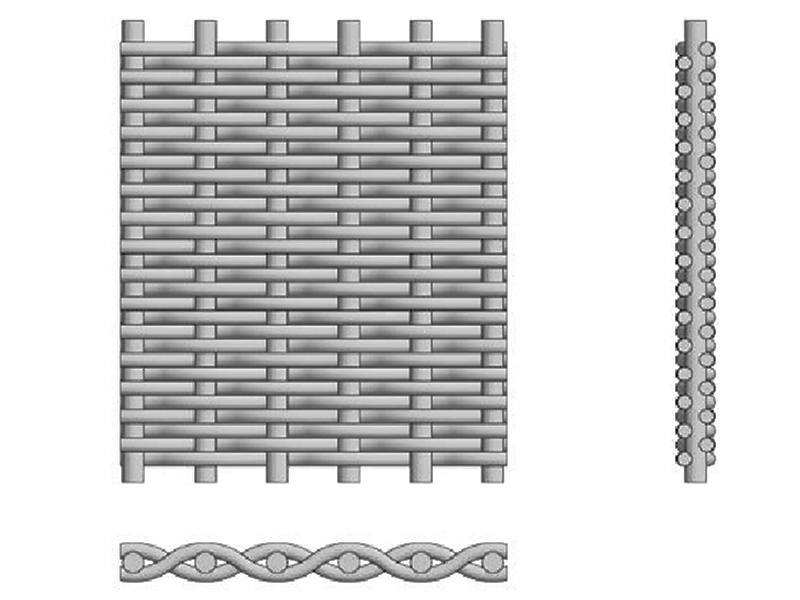

Dutch weaving

The warp wire adopts a thick mesh, the weft wire adopts a fine mesh, and the weft wire alternately passes up and down the two warp wire, forming a fine mesh in one direction, and a thick mesh in the other direction, forming a tight woven mesh with a conical or wedge opening;

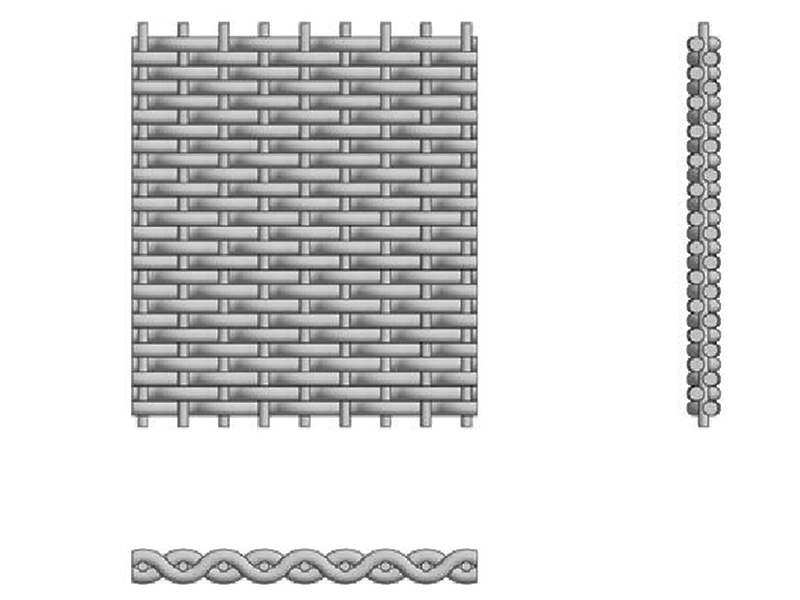

Reverse dutch weave

Contrary to the layout of plain dutch weaving, the warp wire is made of fine mesh(mesh wire, woven wire mesh), the weft wire is made of thick mesh, and the number of wires is relatively small;

Five-Heddle weaving

Each warp wire alternately passes through the top and bottom of each weft wire by 90°. The warp wire and weft wire are the same diameter and the opening size is the same.

Herringbone weave

It is a special twill weave mesh, and the direction of the twill fabric is reversed every 20, 50, 100, 200, 500 mm according to the width and specific use, forming a skeleton shape similar to that of herring;

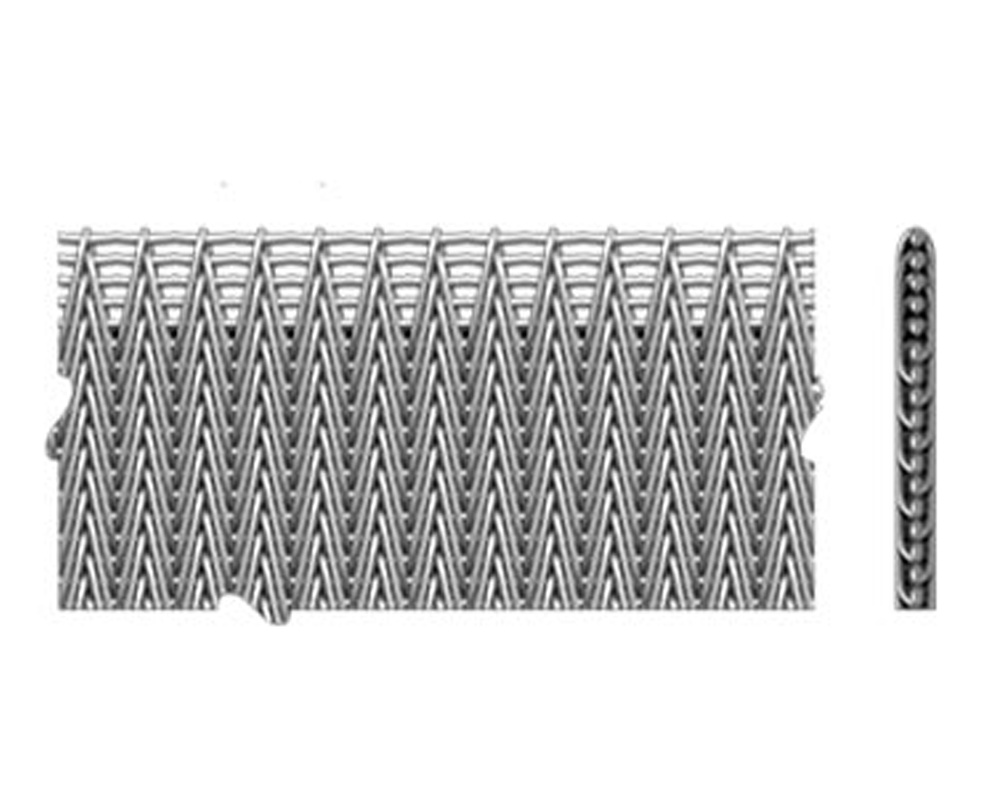

Crimped weave

Heavy metal mesh formed by interlocking or nesting of embossed wire mesh, which is bent at specified intervals during crimping to maintain a precise mesh structure.

According to customer needs, customized stainless steel wire mesh with different weaving methods.

Stainless Steel Wire Mesh Inventory

Anping Guangtong Hardware Wire Mesh Co., Ltd. is a stainless steel wire mesh manufacturer who is commited to professional design, research and development, production, with more than 20 years of experience in wire mesh production and processing field. In metal woven wire mesh’s field has an unshakable leading position, with a wide range of metal woven wire mesh inventory, it can more than 90% of the metal woven wire mesh manufacturers, in a number of inventory warehouses, there are 5000 different types of metal woven wire mesh. There are 3000-4000 types available for tailoring and same-day delivery.

(If we don't have what you need, or if you need a reliable long-term source throughout your supply chain, we can customize it as per your stainless steel wire mesh specifications.)

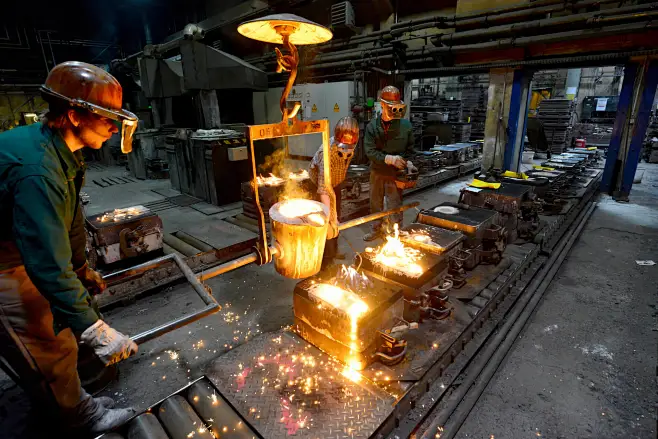

Stainless Steel Wire Mesh Production Capacity

Anping Guangtong Hardware Wire Mesh Co., Ltd. covers an area of 40,000 square meters, with more than 400 weaving machines, an annual capacity of about 3600,000 square meters, has reached a strategic partnership with more than 60 countries in the world. We welcome your inquiries and send us sample requests.

Stainless Steel Wire Mesh Industry Certificate

The company has obtained and fully implemented ISO9001 Quality Management System Certification, ISO45001 Occupational Health And Safety Management System Certification, ISO14001 Environmental Management System Certification, IATF16949 Automotive Industry Quality Management System Certification, AEO customs certification and other related certifications.

Stainless Steel Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Stainless Steel Wire Mesh Application

Stainless steel wire mesh is widely used in mining, chemical, food, pharmaceutical and other industries.

Pharmaceutical Manufacturing

Petroleum

Mining Industry

Metallurgy

Food Processing

Chemical Industry

FAQ

What kind of stainless steel woven wire mesh can you provide?

✔ We offer stainless steel woven mesh made of 304, 304L, 316, 316L, 321, 314, 430 and 904L.

What kinds of woven stainless steel wire mesh do you mainly provide?

✔ We can provide plain weave, twill weave, dutch weave, reverse dutch weave, five-heddle weave and herringbone weave for you to choose from.

Can you provide other stainless steel wire mesh specifications not listed on the website?

✔ Yes. We can provide custom machining services and can provide other stainless steel wire mesh specifications according to your needs.

What is your stainless steel wire mesh price?

✔ Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contacts us for further information.

Can you provide samples of stainless steel wire mesh?

✔ We are glad to provide you with samples for your testing and inspection, and the standard sample size is similar as A4 paper. If you need a larger size, please contact us for a quote.

Stainless steel wire mesh is a highly versatile and durable material widely used across industrial, commercial, and architectural applications. Made from high-quality stainless steel wires, the mesh offers excellent resistance to corrosion, oxidation, and high temperatures while maintaining superior strength, flexibility, and longevity. The combination of these properties makes stainless steel wire mesh suitable for demanding environments where reliability, durability, and precision are critical.

Manufacturing Process

The production of stainless steel wire mesh involves drawing stainless steel into fine wires and weaving them into various mesh patterns. Common weave types include plain weave, twill weave, and dutch weave, each offering unique characteristics in terms of strength, porosity, and filtration capability. Plain weave is the simplest and most common, where the weft wire passes alternately over and under each warp wire. Twill weave, on the other hand, creates a diagonal pattern that allows for tighter openings and greater strength. Dutch weave, with its dense warp and fine weft arrangement, is designed for precise filtration and high-pressure applications.The wires can be made from different grades of stainless steel, such as 304, 316, 316L, and 310, depending on the application requirements. Grade 304 offers excellent corrosion resistance and is suitable for general applications, whereas 316 and 316L are more resistant to chemicals and seawater, making them ideal for marine and chemical processing environments. Grade 310 can withstand extremely high temperatures, suitable for furnace applications.

Key Properties

-

Corrosion Resistance – Stainless steel wire mesh is highly resistant to rust and corrosion, even in harsh environments, including humid, acidic, or saline conditions.

-

High Strength – The woven structure provides excellent mechanical strength and durability, capable of withstanding heavy loads, tension, and mechanical stress.

-

Temperature Resistance – Stainless steel maintains its strength and integrity at both high and low temperatures, making it suitable for applications ranging from freezing environments to high-temperature industrial processes.

-

Chemical Resistance – It can resist corrosion from many chemicals, including acids, alkalis, and salts, which makes it suitable for use in chemical processing plants, laboratories, and filtration systems.

-

Durability and Longevity – With proper care, stainless steel wire mesh can last for decades, reducing maintenance and replacement costs.

Applications

Stainless steel wire mesh is used in a wide array of applications across various industries:-

Filtration and Separation

-

Stainless steel wire mesh is ideal for filtering liquids, gases, and powders in industries such as food processing, pharmaceuticals, chemical processing, and water treatment.

-

Its uniform pore size and consistent weave ensure accurate particle separation and efficient filtration performance.

-

Mesh can be fabricated into cylindrical filter elements, plates, or screens to meet specific filtration needs.

-

-

Screening and Sieving

-

In mining, construction, and metallurgy, stainless steel wire mesh is used for sorting and grading materials according to particle size.

-

Sieving and screening processes rely on the mesh’s uniformity and strength to handle heavy loads and repeated use.

-

-

Architectural and Decorative Applications

-

Stainless steel wire mesh is increasingly popular in architectural design for facades, partitions, ceilings, balustrades, and decorative panels.

-

It offers a combination of transparency, strength, and modern aesthetics, allowing natural light penetration while maintaining security and structural integrity.

-

Its resistance to corrosion makes it suitable for indoor and outdoor architectural features.

-

-

Protective and Security Applications

-

The mesh serves as protective guards for machinery, enclosures, fencing, and security barriers.

-

It provides a strong and durable shield against mechanical impact while ensuring visibility and airflow.

-

-

Industrial Applications

-

Stainless steel wire mesh is widely used in chemical processing, petrochemical plants, and oil refineries due to its resistance to corrosive chemicals and high temperatures.

-

It is also used in heat exchangers, catalyst supports, and other components requiring strength, chemical stability, and thermal tolerance.

-

-

Food and Beverage Industry

-

Mesh is used for sieving, filtering, and separating ingredients, ensuring hygiene and preventing contamination.

-

Stainless steel’s corrosion resistance and non-reactive nature make it ideal for handling food products, oils, and beverages.

-

-

Marine and Offshore Applications

-

Stainless steel wire mesh resists saltwater corrosion, making it suitable for docks, jetties, coastal constructions, and offshore platforms.

-

It is often used for protective barriers, filtration systems, and structural reinforcement in marine environments.

-

Customization and Fabrication

Stainless steel wire mesh can be customized to meet specific requirements:-

Mesh Count and Aperture Size – Fine mesh for microfiltration or coarse mesh for heavy screening.

-

Wire Diameter – Thicker wires for strength or thinner wires for precise filtration.

-

Weave Type – Plain, twill, or dutch weave based on the application.

-

Shape and Form – Sheets, rolls, cylindrical elements, cones, or custom shapes to fit equipment and structures.

-

Surface Finish – Polished, galvanized, or passivated to enhance corrosion resistance and aesthetic appeal.

Maintenance and Longevity

Stainless steel wire mesh is low-maintenance. Regular cleaning using water, mild detergents, or non-abrasive brushes is sufficient to maintain performance and appearance. In industrial environments, high-pressure washing or ultrasonic cleaning can be used for heavily contaminated mesh. Proper maintenance ensures long service life and consistent filtration, screening, or protective performance.Environmental and Sustainability Considerations

-

Stainless steel is 100% recyclable, making wire mesh environmentally friendly.

-

Its long service life reduces material consumption and replacement frequency.

-

Non-toxic and non-reactive, stainless steel wire mesh is safe for food, water, and chemical applications.

Advantages of Stainless Steel Wire Mesh

-

Long-lasting and durable, suitable for harsh environments.

-

High corrosion, heat, and chemical resistance.

-

Versatile applications across industries.

-

Low maintenance and easy cleaning.

-

Customizable in weave, size, material, and finish.

-

Aesthetic appeal for architectural and decorative uses.

Conclusion

Stainless steel wire mesh is an indispensable material in modern industry and architecture. Its combination of strength, corrosion resistance, chemical stability, and aesthetic versatility allows it to meet the most demanding requirements. From filtration, screening, and separation to protective barriers, architectural design, and industrial applications, stainless steel wire mesh continues to provide reliable performance, longevity, and adaptability. Its ability to withstand extreme conditions while maintaining structural integrity ensures that it remains a preferred choice for engineers, architects, and designers worldwide. -

Stainless Steel Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products