Nickel Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Tag list

- 产品描述

-

Nickel Wire Mesh

Nickel wire mesh is made of high quality nickel wire with purity of not less than 99%, based on the excllent chemical and physical properties, nickel wire mesh has good electrical conductivity. Thermal conductivity, ductility and acid and alkali resistance, nickel wire mesh plays a very important role in the field of electrolytic hydrogen production, new energy and fuel cell technology, and is often used in mining, petroleum, chemical, food, pharmaceutical and mechanical lines industry as a metal filter material.

Please refer to the information below, our mesh experts can help you determine the right mesh for your application.

Nickel Wire Mesh Specifications

Chemical Composition of Nickel Type C(%) Cu(%) Fe(%) Mn(%) Ni(%) S (%) Si(%) Co (%) Cr(%) Mg(%) Ti(%) Nickel 200 0.015 0.25 0.40 0.35 99.0 0.01 0.35 - - - - Nickel 205 0.02 0.001 0.005 0.001 99.97 0.001 0.001 0.001 0.001 0.001 0.001 Nickel 270 0.15 0.15 0.20 0.35 99.0 0.008 0.15 - 0.01-0.05 0.01-0.08 - Specification of Nickel 200 Woven Mesh Item Mesh Count Wire Diameter

(in.)Weave Type WidthOpening

(in.)Open Area

(%)NI200-1 8×8 0.0280 Plain 0.0970 60.20 NI200-2 10×10 0.0200 Plain 0.0800 64.00 NI200-3 12×12 0.0140 Plain 0.0693 69.20 NI200-4 16×16 0.0120 Plain 0.0505 65.30 NI200-5 16×16 0.0140 Plain 0.0485 60.20 NI200-6 20×20 0.0045 Plain 0.0455 82.80 NI200-7 20×20 0.0070 Plain 0.0430 74.00 NI200-8 20×20 0.0140 Plain 0.0360 51.80 NI200-9 25×25 0.0060 Plain 0.0190 57.80 NI200-10 26×26 0.0100 Plain 0.0285 54.80 NI200-11 30×30 0.0130 Plain 0.0203 37.20 NI200-12 40×40 0.0060 Plain 0.0190 57.80 NI200-13 40×40 0.0100 Plain 0.0150 36.00 NI200-14 50×50 0.0020 Plain 0.0180 81.00 NI200-15 60×60 0.0070 Plain 0.0097 33.60 NI200-16 60×60 0.0105 Twil 0.0062 13.70 NI200-17 60×60 0.0100 Twill 0.0057 11.60 NI200-18 70×70 0.0040 Plain 0.0103 51.80 NI200-19 70×70 0.0045 Plain 0.0098 46.90 NI200-20 70×70 0.0080 Twill 0.0063 19.40 NI200-21 80×80 0.0055 Twil 0.0070 31.40 NI200-22 85×70 0.0060 Plain 0.0000 28.40 NI200-23 100×100 0.0020 Plain 0.0080 64.00 NI200-24 100×100 0.0040 Plain 0.0060 36.00 NI200-25 100×100 0.0045 Plain 0.0060 30.30 NI200-26 200×200 0.0018 Plain 0.0032 41.00 Specification of Nickel 205 Woven Mesh Item Mesh Count Wire Diameter

(in.)Type Weave Width Opening

(in.)Open Area

(%)NI205-1 60×60 0.0060 Plain 0.0107 41.00 Specification of Nickel 270 Woven Mesh Item Mesh Count Wire Diameter

(in.)Type Weave Width Opening

(in.)Open Area

(%)NI270-1 50×50 0.0670 Plain 0.0133 44.2 NI270-2 60×60 0.0040 Plain 0.0127 57.8 NI270-3 60×60 0.0060 Plain 0.0107 41.0 NI270-4 60×60 0.0070 Plain 0.0097 33.6 NI270-5 75×75 0.0060 Plain 0.0073 30.3 Nickel Wire Mesh Features and Advantages

Excellent electrical conductivity

Nickel is a good conductive material, so nickel wire mesh has excellent conductive properties. This makes nickel mesh in electronics, communications and other fields have a wide range of applications, such as the production of electromagnetic shielding materials, conductive cloth and so on.

High temperature resistance

Nickel wire mesh has a high melting point and high temperature resistance, and can maintain stable physical and chemical properties in high temperature environments. This makes the nickel mesh in chemical, petroleum and other fields of high temperature reactor and catalyst carrier has a unique advantage.

Corrosion resistance

Nickel wire mesh has good corrosion resistance to a variety of chemical media, such as acid, alkali, salt and so on. This make the nickel mesh in chemical, pharmaceutical and other fields of equipment manufacturing and pipeline connection has a wide range of applications.

Strong load capacity

Nickel wire mesh has high tensile strength and fatigue resistance, and can withstand large tensile and compressive forces. This make nickel mesh in the manufacture of filters, screens, protective mesh have a wide range of applications.

Nickel Wire Mesh weaving method

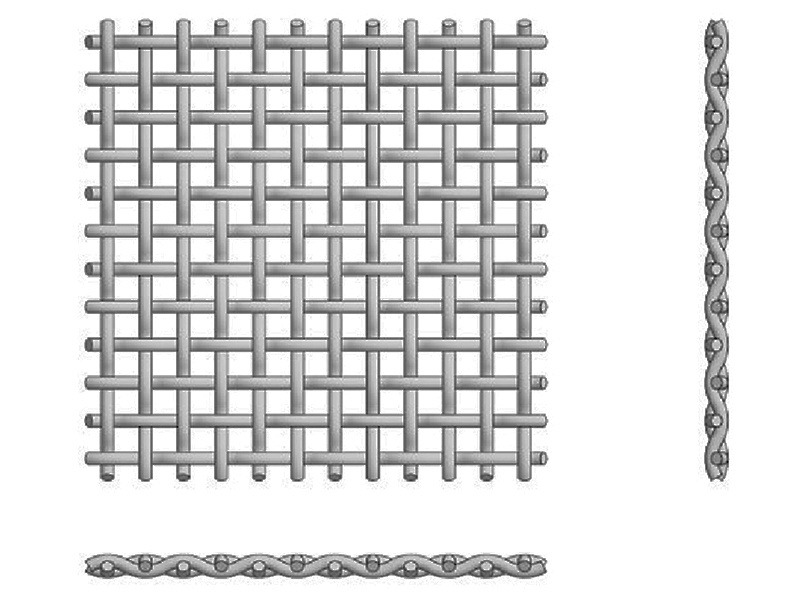

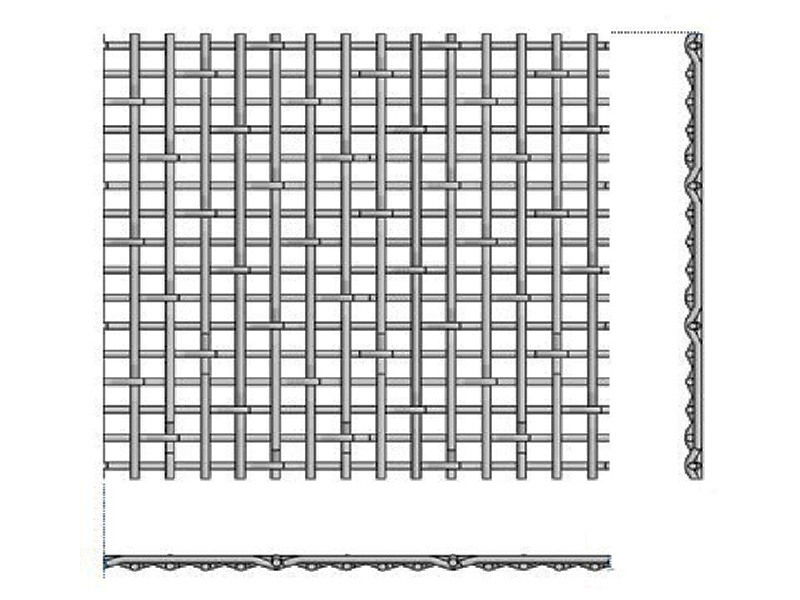

Plain weave

Each warp wire alternately passes through the top and bottom of each weft wire to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same;

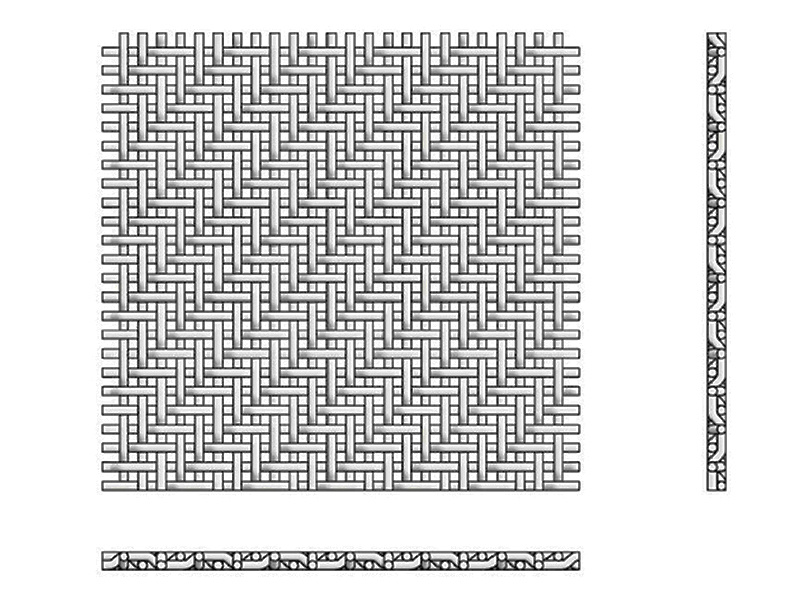

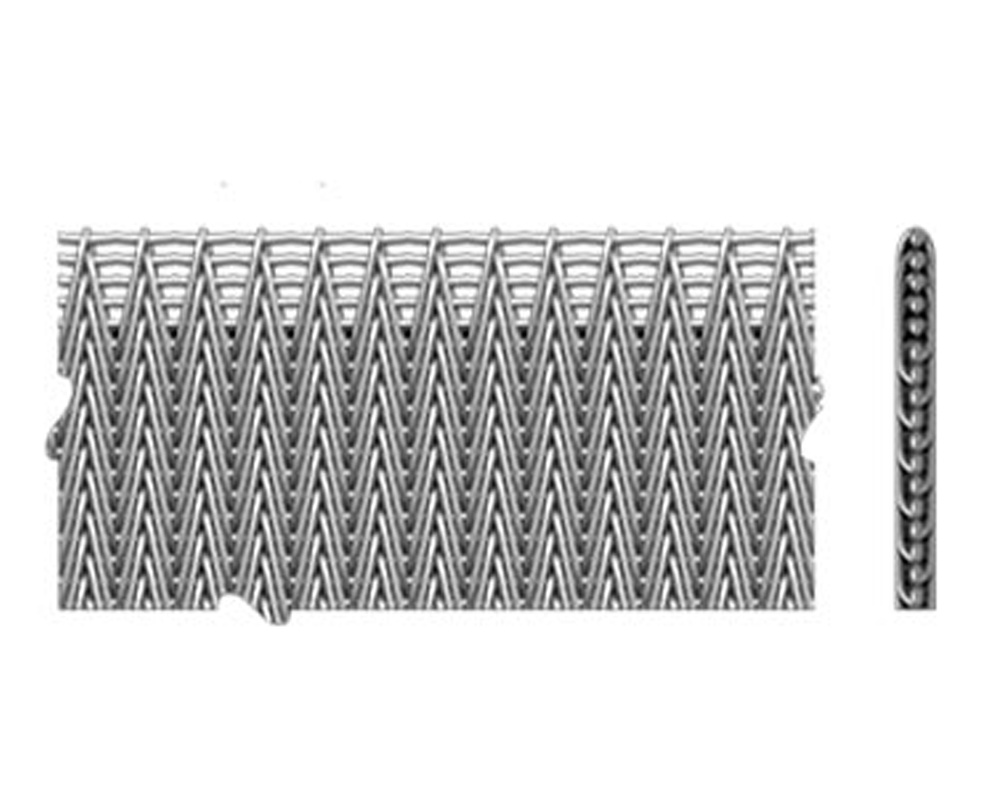

Twill weave

Made by alternating each weft wire up and down two warp wire, interleaving on successive warp wire;

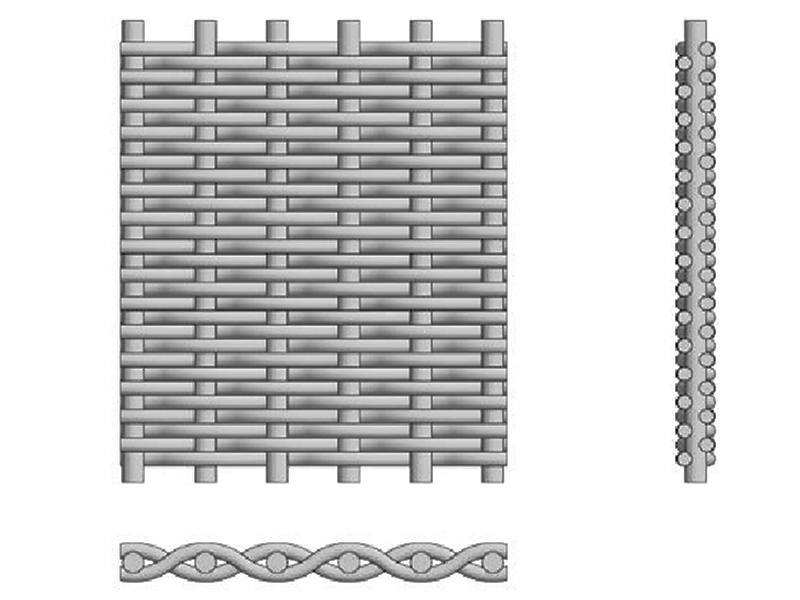

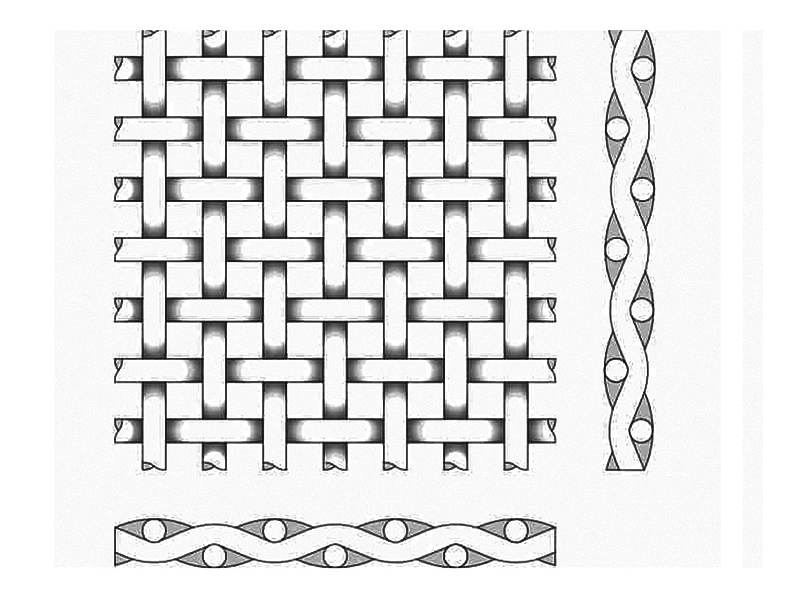

Dutch weaving

The warp wire adopts a thick mesh, the weft wire adopts a fine mesh, and the weft wire alternately passes up and down the two warp wire, forming a fine mesh in one direction, and a thick mesh in the other direction, forming a tight woven mesh with a conical or wedge opening;

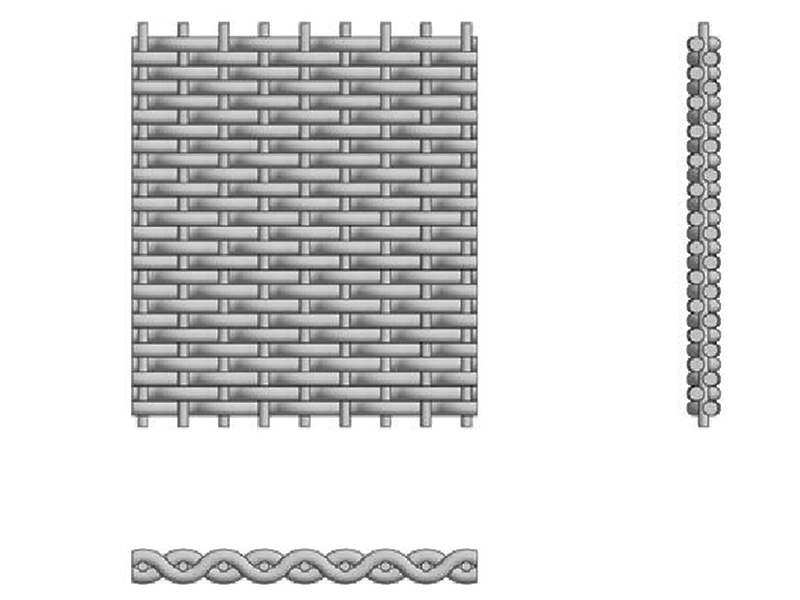

Reverse dutch weave

Contrary to the layout of plain dutch weaving, the warp wire is made of fine mesh (mesh wire, woven wire mesh), the weft wire is made of thick mesh, and the number of wires is relatively small;

Five-Heddle weaving

Each warp wire alternately passes through the top and bottom of each weft wire to be 90°. The warp wire and weft wire are the same diameter and the opening size is the same;

Herringbone weave

It is a special twill weave mesh, and the direction of the twill fabric is reversed every 20, 50, 100, 200, 500 mm according to the width and specific use, forming a skeleton shape similar to that of herring;

Crimped weave

Heavy metal mesh formed by interlocking or nesting of embossed wire mesh, which is bent at specified intervals during crimping to maintain a precise mesh structure.

According to customer needs, customized nickel wire mesh with different weaving methods.

Nickel Wire Mesh Inventory

Anping Guangtong Hardware Wire Mesh Co., Ltd. is a nickel wire mesh manufacturer who is commited to professional design, research and development, production, with more than 20 years of experience in wire mesh production and processing field. In metal woven wire mesh’s field has an unshakable leading position, with a wide range of metal woven wire mesh inventory, it can more than 90% of the metal woven wire mesh manufacturers, in a number of inventory warehouses, there are 5000 different types of metal woven wire mesh. There are 3000-4000 types available for tailoring and same-day delivery.

(If we don't have what you need, or if you need a reliable long-term source throughout your supply chain, we can customize it as per your nickel wire mesh specifications.)

Nickel Wire Mesh Production Capacity

Anping Guangtong Hardware Wire Mesh Co., Ltd. covers an area of 40,000 square meters, with more than 400 weaving machines, an annual capacity of about 3600,000 square meters, has reached a strategic partnership with more than 60 countries in the world. We welcome your inquiries and send us sample requests.

Nickel Wire Mesh Industry Certificate

The company has obtained and fully implemented ISO9001 Quality Management System Certification, ISO45001 Occupational Health And Safety Management System Certification, ISO14001 Environmental Management System Certification, IATF16949 Automotive Industry Quality Management System Certification, AEO customs certification and other related certifications.

Nickel Wire Mesh Packaging

Inner paper tube & Waterproof paper & Plastic film & Plywood case & Pallet

Nickel Wire Mesh Applications

Nickel wire mesh is often used in the electronic information industry such as fuel cells, and is also widely used in petroleum, chemical, aerospace, new energy and other industries.

Petroleum

Natural Gas

Battery Industry

Chemical Industry

Aviation

Aerospace

FAQ

Can you provide other nickel wire mesh specifications not listed on the website?

✔ Yes, we can provide custom machining services and can provide other nickel wire mesh specifications according to your needs.

What support can you provide in terms of the quality of the nickel wire mesh produced by your company?

✔ We will carry out strict quality control in the raw material entering the factory and the production process to reduce the quality loss as much as possible.

How does your company calculate shipping costs?

✔ Shipping costs depend on the pickup method you choose. Express delivery is usually the fastest way, but it is also the most expensive. Sea transportation is the best solution for large quantities of goods, only by knowing other details such as quantity, weight, etc., we can give you: accurate shipping costs. Please contact us for more information.

Do you offer price discounts for large orders?

✔ Yes, you can contact one of our sales representatives to discuss this in detail.

What materials of nickel wire mesh can you provide?

✔ The nickel wire mesh we produce is made of high-quality nickel wire with a purity of not less than 99% by default. We will also provide Ni4, Ni6, nickel-chromium wire, nickel-copper wire and other materials according to your needs.

Nickel wire mesh is a high-performance woven metal mesh made entirely from nickel, a corrosion-resistant and heat-resistant metal known for its mechanical strength and chemical stability. Nickel wire mesh is widely used in industries where durability, corrosion resistance, and chemical inertness are essential, such as chemical processing, petrochemical, food processing, pharmaceuticals, electronics, aerospace, and marine applications. Its excellent mechanical properties, resistance to oxidation, and high-temperature tolerance make nickel wire mesh an ideal choice for filtration, screening, catalyst support, protective barriers, and electronic shielding applications.

Material Composition and Properties

Nickel wire mesh is composed of pure nickel or high-grade nickel alloys. The properties of nickel make it highly suitable for challenging environments:

-

Corrosion Resistance – Nickel is highly resistant to corrosion in acidic, alkaline, and saline environments. This makes it ideal for chemical processing, marine, and high-humidity conditions.

-

High Temperature Tolerance – Nickel can withstand elevated temperatures without losing structural integrity or mechanical strength, making it suitable for high-temperature filtration and industrial applications.

-

Mechanical Strength – Nickel’s high tensile strength provides excellent durability and resistance to mechanical stress.

-

Chemical Inertness – Nickel does not easily react with most chemicals, allowing it to be used in aggressive chemical environments.

-

Electrical Conductivity – While not as conductive as copper, nickel still provides moderate electrical conductivity, suitable for certain electronic or EMI shielding applications.

Key Features of Nickel Wire Mesh

-

Durability – Resistant to wear, abrasion, and mechanical stress.

-

Corrosion and Oxidation Resistance – Performs well in harsh chemical, marine, and industrial environments.

-

High Temperature Resistance – Can operate reliably in extreme heat applications.

-

Uniform Aperture Size – Precision weaving ensures consistent mesh openings for accurate filtration and screening.

-

Customizable – Wire diameter, mesh count, weave pattern, and form factor can be adjusted to meet specific requirements.

-

Versatile Applications – Can be used in filtration, chemical processing, aerospace, electronics, protective screens, and architectural designs.

Manufacturing Process

The production of nickel wire mesh requires precise control over wire quality, diameter, and weaving patterns to ensure optimal performance:

-

Wire Drawing – Nickel wire is drawn through precision dies to achieve the required diameter and tensile strength.

-

Annealing – Heat treatment improves flexibility and ductility, preventing breakage during weaving.

-

Weaving – Wire is woven into mesh using mechanical or automatic looms. Different weave patterns can be used depending on the application:

-

Plain Weave – Simple over-and-under pattern, uniform openings, balanced strength.

-

Twill Weave – Diagonal pattern providing finer filtration and enhanced mechanical strength.

-

Dutch Weave – Dense weave suitable for high-pressure filtration and precision separation.

-

-

Finishing – The mesh may undergo cleaning, polishing, or coating to improve surface quality, corrosion resistance, and aesthetics.

Applications of Nickel Wire Mesh

-

Chemical and Petrochemical Industry

-

Nickel wire mesh is used in filtration of acids, alkalis, solvents, and other corrosive chemicals.

-

Suitable for catalyst support, gas or liquid filtration, and separation processes.

-

-

High-Temperature Filtration

-

Ideal for furnace filters, high-temperature exhaust systems, heat exchangers, and other applications requiring thermal stability.

-

-

Marine Applications

-

Resistant to saltwater corrosion, making it suitable for offshore platforms, ship components, and marine filtration systems.

-

-

Aerospace and Aviation

-

Nickel wire mesh is used in aerospace applications where heat resistance, chemical stability, and structural integrity are critical.

-

Commonly applied in fuel filters, ventilation screens, and protective shields.

-

-

Electronics and EMI/RFI Shielding

-

Nickel mesh can serve as a conductive screen for electromagnetic interference shielding.

-

Suitable for electronic enclosures, circuit boards, and sensitive equipment.

-

-

Food and Pharmaceutical Industry

-

Nickel’s chemical inertness ensures safe filtration of food products, beverages, and pharmaceuticals.

-

Used in sieving, straining, and separation of powders or liquids.

-

-

Industrial Filtration and Screening

-

Applied in water treatment, oil refining, chemical processing, and other industrial filtration systems.

-

Provides precise separation of particles while resisting corrosion and mechanical wear.

-

-

Protective Screens and Safety Barriers

-

Nickel wire mesh can be used in machinery guards, ventilation panels, protective enclosures, and architectural designs.

-

Advantages of Nickel Wire Mesh

-

High corrosion resistance in acidic, alkaline, and saline environments.

-

Excellent mechanical strength and durability under stress.

-

Heat resistance suitable for high-temperature industrial applications.

-

Chemical inertness ensures long-lasting performance in aggressive environments.

-

Uniform mesh openings allow precise filtration and particle separation.

-

Versatile and customizable for various applications.

-

Long service life and low maintenance requirements.

Customization Options

Nickel wire mesh can be tailored to specific operational needs:

-

Mesh Count – Fine mesh for precise filtration or coarse mesh for screening.

-

Wire Diameter – Thick wires for structural support, thin wires for precision filtration.

-

Weave Type – Plain, twill, Dutch, or reverse Dutch weave depending on strength and filtration needs.

-

Form Factor – Sheets, rolls, cylindrical elements, panels, or custom shapes.

-

Surface Treatment – Polishing, coating, or passivation to enhance durability and corrosion resistance.

Maintenance and Longevity

Nickel wire mesh requires minimal maintenance due to its robust and corrosion-resistant properties. Routine cleaning with water, mild detergents, or ultrasonic cleaning can maintain performance. In high-temperature or chemical applications, nickel mesh maintains its integrity over extended periods, offering long-term reliability and cost efficiency.

Environmental and Sustainability Considerations

-

Nickel is recyclable, and nickel wire mesh can be reused or reprocessed at the end of its service life.

-

Durable design reduces the frequency of replacement and minimizes material waste.

-

Safe for food, pharmaceutical, and water treatment applications.

Applications Summary Table

Application Area Benefits Examples Chemical & Petrochemical Corrosion resistance, chemical inertness Acid/alkali filtration, catalyst support High-Temperature Systems Heat resistance, mechanical stability Furnaces, heat exchangers, exhaust filters Marine Saltwater resistance Offshore platforms, ship filtration Aerospace & Aviation Thermal & chemical stability Fuel filters, ventilation screens, protective shields Electronics & EMI/RFI Conductive shielding Electronic enclosures, circuit boards Food & Pharmaceutical Safety, inertness Sieving, filtration of liquids and powders Industrial Filtration Precise particle separation Oil refining, water treatment, chemical processing Protective Screens Durability, strength Machine guards, ventilation panels, architectural designs Conclusion

Nickel wire mesh is a high-performance, corrosion-resistant, and heat-resistant metal mesh suitable for a wide range of demanding applications. Its mechanical strength, chemical inertness, and uniform mesh openings make it ideal for filtration, separation, protective barriers, and electronic shielding. Customizable in wire diameter, mesh count, weave type, and form factor, nickel wire mesh can meet the specific requirements of chemical processing, petrochemical, food and pharmaceutical, marine, aerospace, and industrial filtration applications. Its durability, versatility, and long-term reliability make nickel wire mesh a preferred choice for engineers, designers, and industrial operators worldwide.

-

Nickel Wire Mesh

If you need customized wire mesh products, Contact US !

Products Category

Tag list

Request a Quote

We will contact you within one working day. Please pay attention to your email.

Related Products