Metal Sintered Filter

If you need customized wire mesh products, Contact US !

Products Category

- 产品描述

-

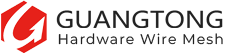

Metal Sintered Filter

Metal Sintered Filter is made of metal powder as raw material and a conventional combination of five-layer sintering mesh with high temperature vacuum sintering, pressing and calendering. The process combines heat and pressure, no adhesive is added, and the multi-layer mesh is permanently bonded to obtain a sintered material with the required strength and performance, while being equipped with different connectors, stable in shape and good in air permeability, making it an ideal material for purification and filtration. The most commonly used sintered metal materials are stainless steel and brass. As a professional metal filter manufacturer, our sintered metal materials also include titanium-nickel, monel, and other materials to ensure excellence and reliability in harsh environments. If you are interested in further discussing the technical details of metal sintered filters or cooperation opportunities, please feel free to contact us.

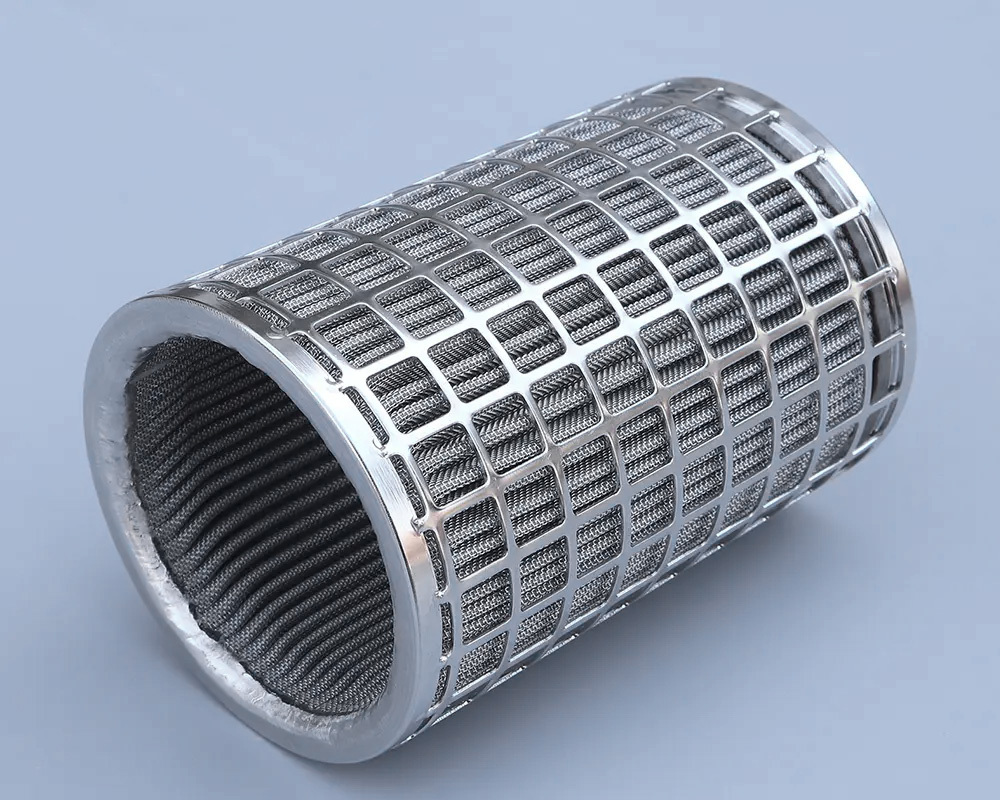

Metal Sintered Filter Specifications

*Filtration rate: 1-300μm

*Diameter: 14-800mm

*Length: 35-1500mm

*Other diameters and lengths are available upon request

Metal Sintered Filter Structure Type

·Five-layer and multi-layer: the main difference is the strength and filtration accuracy;

·Woven wire mesh: highly flexible for filters with complex shapes;

·Perforated metal: enhanced mechanical strength, suitable for high-pressure environments;

·Pleated pore structure: provides a larger filtration surface area.

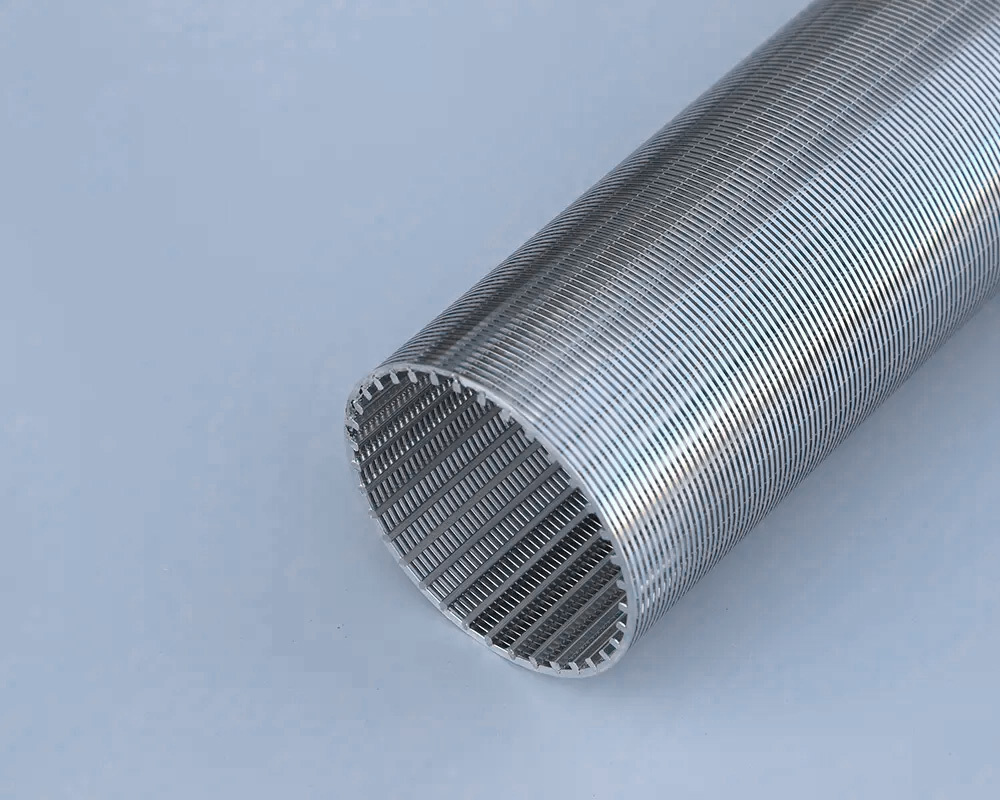

Metal Sintered Filter Configuration

Standard connector: 215, 222, 226, etc.

Threaded connectors: M20, M30, M32, M42. etc.

Flat/DOE type.

Special custom connectors.

Metal Sintered Filter Material

Stainless steel (304, 304L, 316, 316L, 904L, etc.): strong corrosion resistance, suitable for a variety of chemical environments;

Brass: has good mechanical properties and electrical conductivity;

Nickel: has good stability in high temperature environment;

Other alloys: customized to your specific needs.

These are regular metal sintered filter specifications and can be customized to meet your specific filtration needs.

Metal Sintered Filter Features and Advantages

High filtration rate

The pore size of our metal sintered filter core is distributed in 1-300μm, with uniform pores and stable internal structure, ensuring high filtration rate and efficient removal of fine particles;

High temperature and corrosion resistance

Metal sintered filter material is metal powder, which is born with excellent high temperature and corrosion resistance, and can maintain stable working performance in high temperature, high pressure, acid and alkali and other harsh environments;

High mechanical strength

Metal sintered filter through vacuum sintering, calendering and other processes, to ensure that it has excellent impact resistance to harsh environments, to ensure the stability and long service life in high pressure and high corrosion environment;

Good purification effect

Combined with heat and pressure, under the premise of not adding adhesive, the multi-layer mesh is permanently bonded, stable shape, good air permeability, is the ideal material for purification and filtration;

Various materials, shapes and connection sizes can be customized

A wide selection of materials (such as stainless steel, bronze, nickel, etc.) is available, as well as customized services in different shapes and sizes to meet the needs of specific applications.

Metal Sintered Filter Processing Process

Cutting: according to the size and shape of the metal sintered filter, use the cutting machine or scissors to cut the metal filter plate into the appropriate size and shape, to ensure the precision and smooth surface of the metal sintered filter;

Welding: the cut metal filter plate is welded into a complete metal filter structure by plasma welding process to ensure the sealing and structural stability of the metal sintered filter;

Molding: the cut metal filter plate is placed on the made metal mold to make a metal filter structure to ensure that the metal sintered filter specifications meet the requirements;

Bubble point test: put the welded metal filter element (filter accuracy <50μm) into the machine bearing 100% ethylene propyl alcohol pressure test the tightness of the metal filter pass and weld, to avoid the metal sintered filter element does not meet the sealing requirements.

Metal Sintered Filter Production Capacity

Anping Guangtong Hardware Wire Mesh Co., Ltd. is a professional design, research and development, production, custom metal sintering filter manufacturer, the plant covers an area of 40,000 square meters, with an annual output value of $21 million, with a professional R & D team, support different specifications of metal sintering filter customization, has reached a strategic partnership with more than 60 countries in the world, welcome to inquire and sample request.

Metal Sintered Filter Certificate

The company has obtained and fully implemented ISO9001 Quality Management System Certification, ISO45001 Occupational Health And Safety Management System Certification, ISO14001 Environmental Management System Certification, IATF16949 Automotive Industry Quality Management System Certification, AEO customs certification and other related certifications.

(If we don't have what you need, or you need a reliable long-term source throughout your supply chain, we can customize to your metal sintered filter specifications.)

Metal Sintered Filter Packaging

Plastic film & Plywood case

Metal Sintered Filter Applications

Sintered mesh filter element is mainly used for filtration in polyester, petroleum, chemical, pharmaceutical and other industries, and can also be used for pure water and gas filtration.

Chemical industry

Gas

Petroleum

Food Processing

Water Filtration

Pharmaceutical Manufacturing

FAQ

How does your company maintain a good long-term business relationship with us?

✔ We maintain good quality and competitive prices as the guideline to ensure that our customers benefit.

What is the production capacity of your company? How can l ensure timely delivery of my goods?

✔ Supply capacity: 100,000 pieces/month, we have a mature metal sintered filter supply chain, fully protect your order.

Do you offer bubble point test?

✔ Of course, we support the bubble point test to fully test the tightness of our metal sintered filter element.

What is the mode of transport?

✔ We cooperate with professional logistics companies to provide export, air and sea freight. We can help you with shipping and customs requirements.

Does your company support factory visits?

✔ Yes, you are welcome to visit our factory, and we offer free hotels and free cars.

Metal Sintered Filter

If you need customized wire mesh products, Contact US !

Products Category

Request a Quote

We will contact you within one working day. Please pay attention to your email.