How to Choose a Metal Sintered Filter

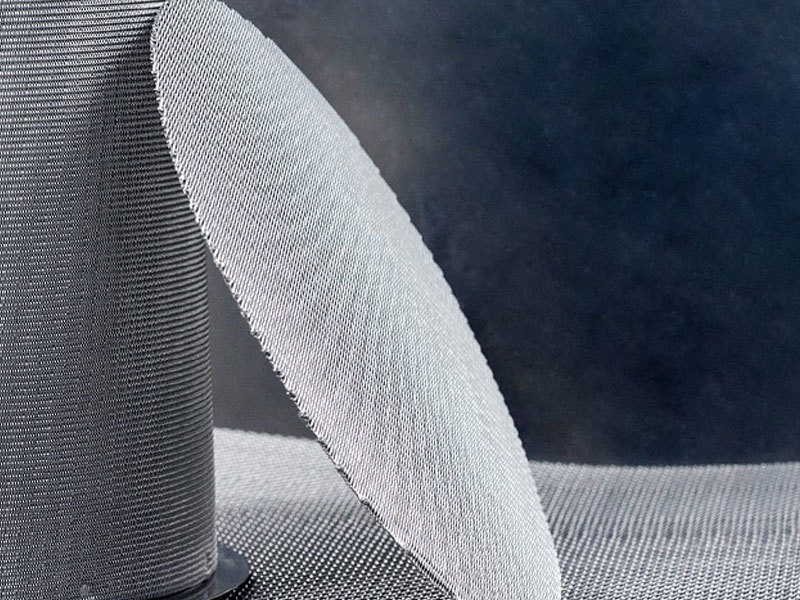

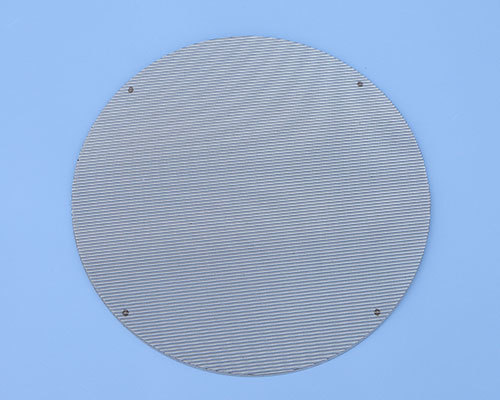

Metal sintered filters are renowned for their durability, high-temperature tolerance and corrosion resistance, and are applicable in various industries including petroleum and natural gas, pharmaceuticals, and food processing. After clarifying the specific application requirements, when choosing metal sintered filters, the following are some key factors that need to be considered.

Material composition

When choosing a metal sintered filter, the first thing to consider is its raw material. Common materials include stainless steel, brass, bronze, aluminum, etc. Among them, stainless steel is the preferred choice due to its corrosion resistance and tensile strength. When selecting the raw material, it is essential to assess its chemical compatibility with the liquid or gas that the metal sintered filter will come into contact with.

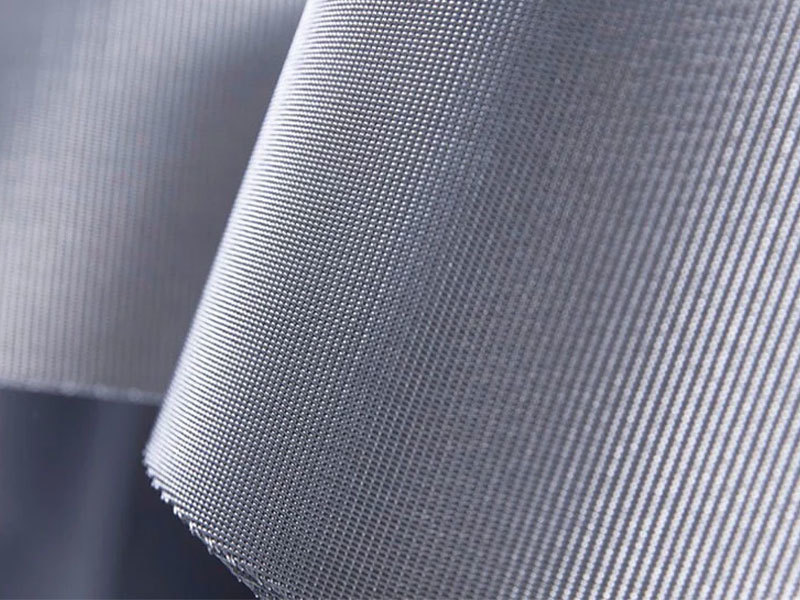

Aperture size and filtering capacity

The pore size of the metal sintered filter element determines its filtration rate. A smaller pore size can achieve a more precise filtration effect. However, after the filtration process, the pressure may increase. Therefore, starting from the pollutants to be removed, select and choose a pore size that can not only ensure the filtration efficiency but also meet the flow rate requirements.

Flow rate and pressure drop

Evaluate the required flow for your application. If the restriction on flow imposed by the sintered metal filter is too high, it may lead to low efficiency and increased operating costs. Please look for a sintered metal filter that can meet your flow requirements while maintaining a low pressure loss.

Temperature and pressure levels

Select metal sintered filter elements that can withstand the operating temperature and pressure of your system. In industries such as petroleum and chemicals, which require dealing with extreme conditions, it is essential to design metal sintered filters with high temperature resistance and high pressure tolerance.

Maintenance and cleaning

The convenience of maintenance and cleaning is also something that needs to be taken into account. Some metal sintered filters are designed with back-washing functions or are easy to clean, which can save time and reduce downtime during operation.

By carefully considering these factors, you will be able to select a metal sintered filter that meets your requirements. Anping Guangtong Hardware wire Mesh Co., Ltd., as a metal filtration manufacturer, can provide the necessary equipment and accessories, ensuring that your application achieves optimal performance during operation and has a long service life.

TAG:

Related Posts

Information about applications of woven wire mesh

No. 56, Weiyi Road, East of Economic Development Zone, Anping, Hebei, China.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.