The Production Process of Epoxy Coated Wire Mesh

Epoxy coated wire mesh boasts excellent durability, corrosion resistance and aesthetic appeal, and has been widely adopted in various industries. The production process of epoxy coated wire mesh is meticulous and efficient, so it involves multiple key steps during its manufacturing to ensure that the final product meets high-quality standards.

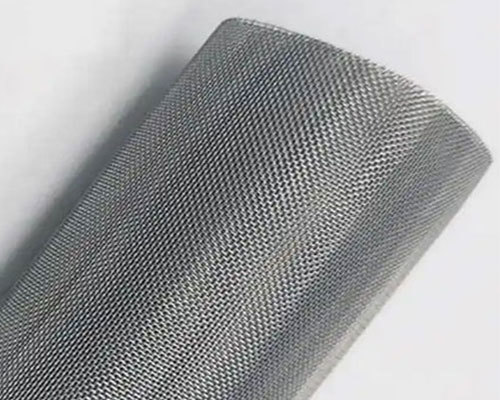

The first step in epoxy coated wire mesh fabrication is to select the base material. Typically, high-quality stainless steel wire is chosen. This is because stainless steel wire has excellent strength and flexibility, which can ensure the stability of the mesh structure of the epoxy coated wire mesh. Subsequently, the stainless steel wire is stretched to the required diameter to ensure consistent dimensions throughout the production process.

Once the stainless steel wire is ready, a thorough cleaning process will be carried out. This includes removing any impurities, oil stains or rust that may affect the adhesion of the epoxy coated wire mesh. The entire cleaning process involves steps such as chemical treatment and water rinsing, ensuring a clean and tidy surface.

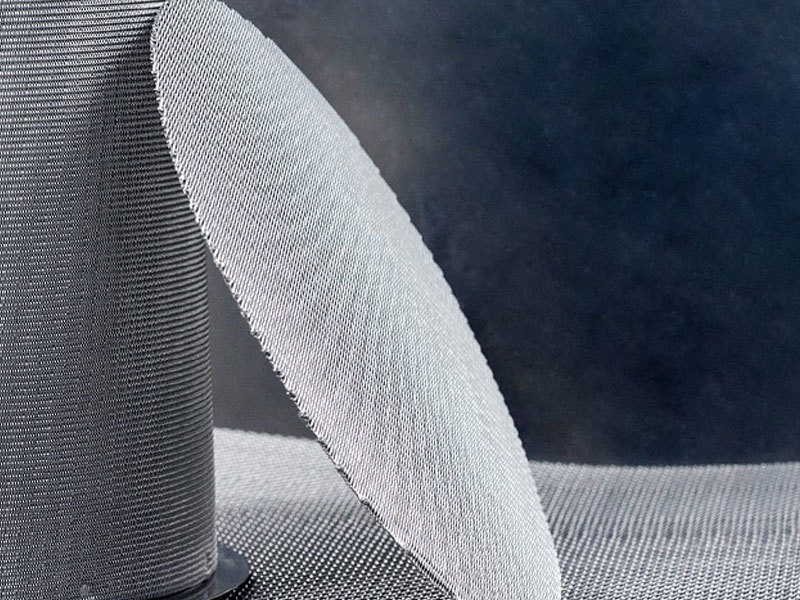

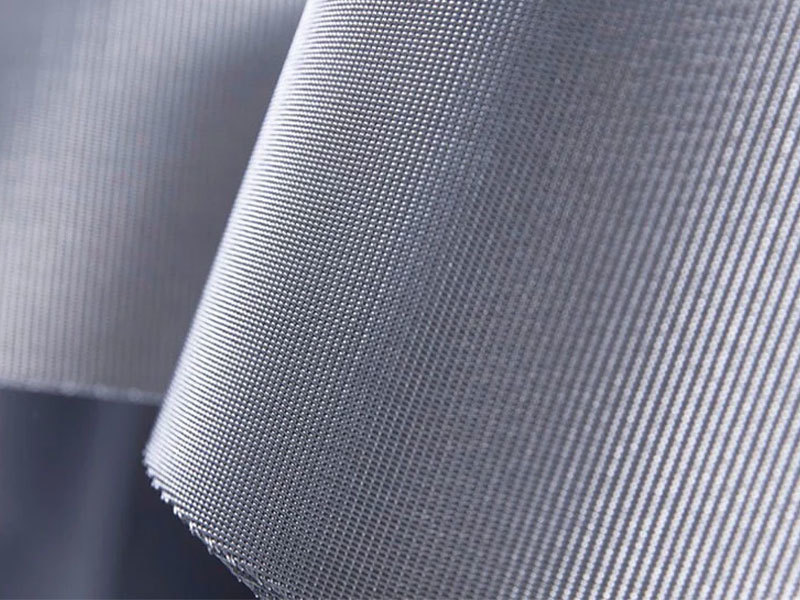

After the cleaning process is completed, the metal wires will be woven into a mesh pattern. This weaving technique is of crucial importance and is also influenced by the intended use of the epoxy coated wire mesh. The weaving process of the wire mesh creates a mesh structure that is both strong and stable, while also ensuring air circulation and clear visibility.

Next, comes the application of the epoxy coating. Usually, the electrostatic spraying process is adopted, where the epoxy resin is sprayed onto the metal mesh surface with an electric charge. This operation method ensures a uniform and consistent coating, which is beneficial for fully exerting the protective performance of the epoxy. After the spraying is completed, it is subjected to oven treatment to solidify the coating, thus enabling the epoxy to firmly adhere to the metal mesh.

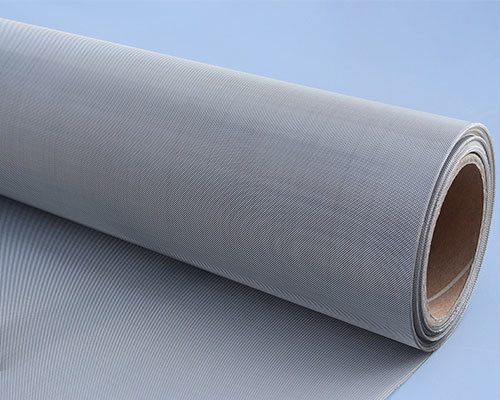

Finally, the quality inspection of epoxy coated wire mesh is of vital importance to ensure that it meets the standards. This includes checks for uniformity of coating thickness, adhesion, and overall appearance. Once quality is ensured to be qualified, the epoxy coated wire mesh is cut to the required size and packaged for shipment.

In conclusion, the production process of epoxy coated wire mesh is a meticulous procedure that combines advanced techniques and quality materials to create a product that meets the demands of various applications, from construction to decorative uses. Anping Guangtong Hardware Wire Mesh Co., Ltd. as a woven wire mesh manufacturer, can provide the required equipment and accessories, ensuring their durability and reliability in the coming years. You can select the appropriate epoxy coated wire mesh according to your own needs.

TAG:

Related Posts

Information about applications of woven wire mesh

No. 56, Weiyi Road, East of Economic Development Zone, Anping, Hebei, China.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.