The Production Process of Three Layer Sintered Mesh

The three-layer sintered net possesses outstanding performance and excellent durability, and is an advanced filtering material that has gained significant attention in numerous industrial applications. To ensure the effectiveness and reliability of the three-layer sintered mesh, its production process involves multiple key steps.

High-quality metal powder

During the production process, high-quality metal powder, usually stainless steel powder, should be selected. Since the particle size and distribution of these powders will affect the final performance of the three-layer sintered mesh, special attention will be paid during the selection process, which is crucial for manufacturing a sturdy three-layer sintered mesh.

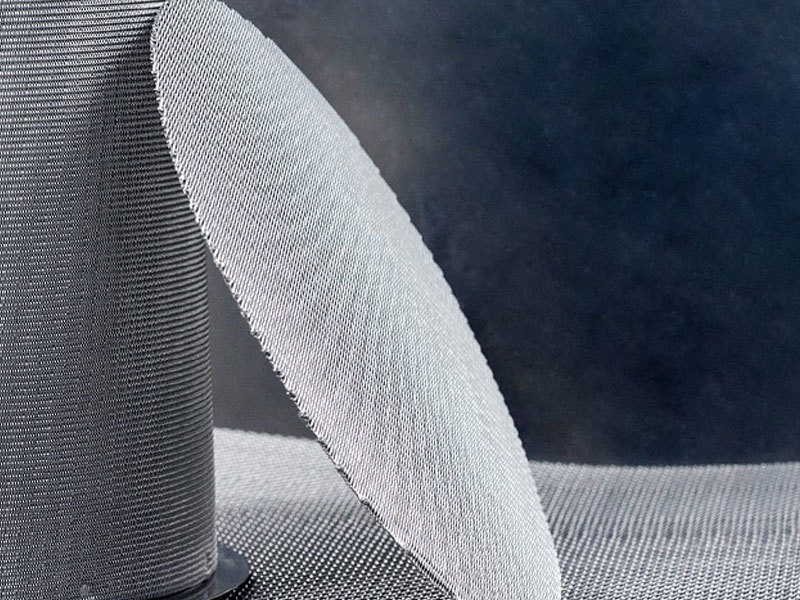

Three-layer sintered mesh is layered

The "layering" process of the 30% sintered mesh is also an important step in its production. During this stage, a three-layer mesh structure with varying pore sizes is formed. Usually, the top layer is designed to capture larger particles, with the smallest pores. The bottom layer is for facilitating fluid flow, with larger pores, while the middle layer serves as a support, This multi-layered sintered mesh no tonly improves the filtration efficiency but also extends its service life.

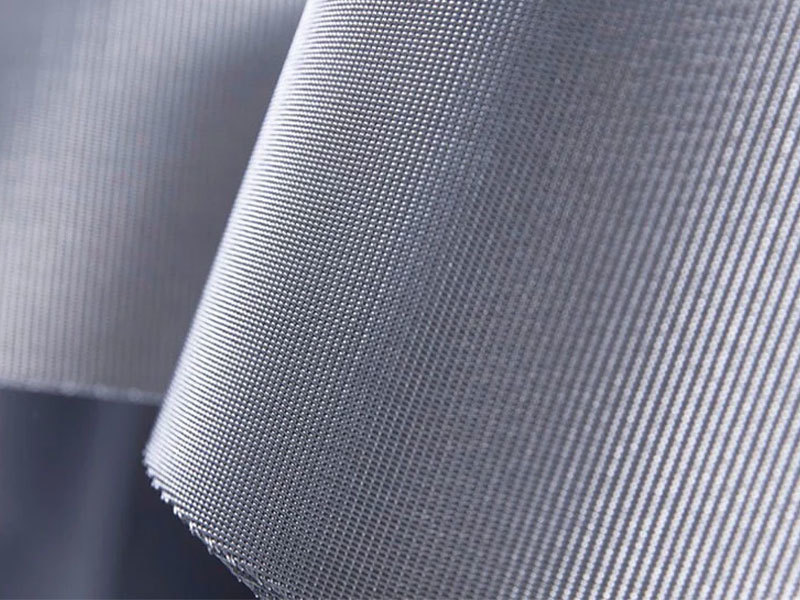

Three-layer sintered mesh sintering

After the layering process, the next step is the sintering process. The layered mesh structure is heated to a high temperature in a controlled environment, allowing the metal particles to bond together without melting. This process enhances the strength of the mesh structure while ensuring its integrity in terms of shape and structure under pressure.

Quality control tests for the three-layer sintered mesh

The final process of the three-layer sintered mesh is to undergo a series of quality control tests to ensure it complies with industry standards. These tests cover the assessment of parameters such as porosity, tensile strength and filtration efficiency. Once the tests are passed, it will be put into use in various applications.

In conclusion, the production process of the three-layer sintered mesh is an extremely meticulous procedure resulting in an efficient filtration solution that can meet the demands of modern industry. Guangtong, as a sintered mesh manufacturer, can provide the required equipment and accessories, you can choose the right three-layer sintered mesh according to your needs.

TAG:

Related Posts

Information about applications of woven wire mesh

No. 56, Weiyi Road, East of Economic Development Zone, Anping, Hebei, China.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.