Nickel Wire Mesh Drives Innovation in High-Performance Industrial Filtration and Protection

Nickel wire mesh is gaining strong momentum across global industrial markets as manufacturers and engineers seek materials capable of performing reliably in extreme environments. Known for its excellent corrosion resistance, thermal stability, and electrical conductivity, nickel wire mesh has become an essential solution in industries ranging from chemical processing and energy production to electronics and aerospace. As industrial systems continue to operate under higher temperatures, stronger chemical exposure, and stricter safety standards, nickel wire mesh is increasingly recognized as a high-value material that balances performance, durability, and adaptability.

One of the most significant advantages of nickel wire mesh is its outstanding resistance to corrosion and oxidation. Pure nickel forms a stable oxide layer on its surface, which effectively protects the material from further chemical attack. This property allows nickel wire mesh to perform exceptionally well in acidic and alkaline environments, as well as in high-humidity or high-temperature conditions where other metals may degrade rapidly. As a result, nickel wire mesh is widely used in chemical filtration systems, catalyst supports, and protective screens in aggressive processing environments.

Thermal performance is another key factor driving the adoption of nickel wire mesh. Nickel maintains its mechanical strength and structural stability over a wide temperature range, making it suitable for applications involving extreme heat or rapid temperature fluctuations. In high-temperature furnaces, heat treatment equipment, and thermal insulation systems, nickel wire mesh provides reliable support and filtration without losing integrity. Its resistance to thermal fatigue helps extend equipment lifespan and reduces the risk of unexpected failures, which is critical for continuous industrial operations.

Nickel wire mesh also plays an important role in electrical and electronic applications due to its stable electrical conductivity and magnetic properties. It is commonly used in battery manufacturing, electromagnetic shielding, and electronic component protection. In emerging sectors such as electric vehicles, renewable energy storage, and advanced electronics, nickel wire mesh supports precise current control, heat dissipation, and structural reinforcement. Its ability to combine mechanical strength with functional electrical performance makes it a versatile material for modern technology-driven industries.

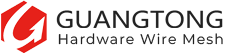

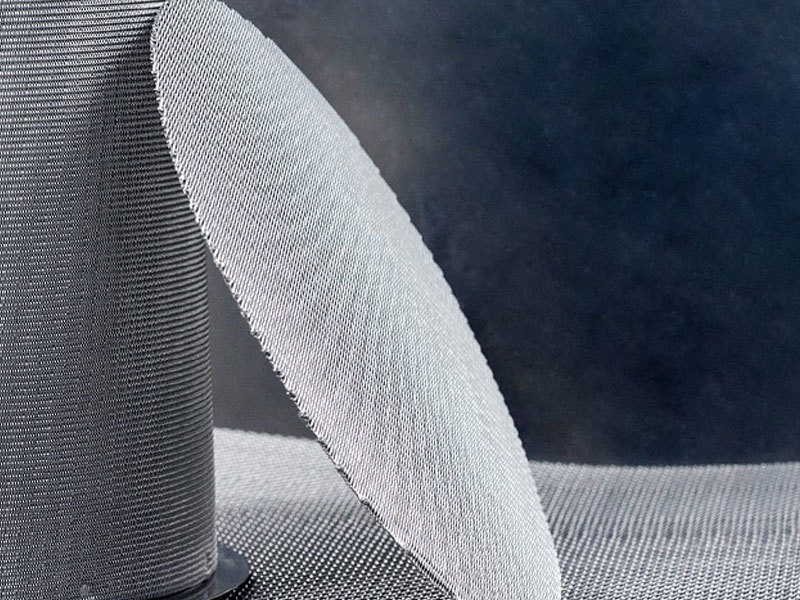

Manufacturing flexibility further enhances the market appeal of nickel wire mesh. It can be produced in a wide range of wire diameters, mesh counts, and weaving patterns, including plain weave, twill weave, and Dutch weave. This allows engineers to tailor filtration accuracy, airflow, and mechanical strength to specific application requirements. Whether used as a fine filtration medium in chemical reactors or as a durable protective mesh in industrial equipment, nickel wire mesh can be customized to deliver consistent and reliable performance.

From an economic perspective, nickel wire mesh offers long-term cost advantages despite its higher initial material cost. Its durability, resistance to wear, and low maintenance requirements reduce the frequency of replacement and downtime. In industries where equipment reliability directly impacts productivity and safety, investing in nickel wire mesh often results in lower total operating costs over the product lifecycle. As companies increasingly focus on long-term value rather than short-term savings, demand for high-performance materials such as nickel wire mesh continues to rise.

Sustainability considerations also support the growing use of nickel wire mesh. Nickel is a recyclable material, and wire mesh products can be recovered and reused at the end of their service life. The long lifespan of nickel wire mesh reduces material waste and resource consumption, aligning with global trends toward environmentally responsible manufacturing and circular economy practices. These attributes make nickel wire mesh not only a technically superior choice but also a sustainable one.

Looking ahead, the outlook for nickel wire mesh remains positive as industrial technologies advance and operating conditions become more demanding. Growth in chemical engineering, clean energy, electric vehicles, and advanced manufacturing is expected to further expand its application scope. With continuous improvements in material processing and weaving technology, nickel wire mesh is set to play an increasingly important role in supporting safe, efficient, and innovative industrial systems worldwide.

TAG:

Related Posts

Information about applications of woven wire mesh