Monel Wire Mesh Expands Its Role in High-Performance Industrial Applications

Monel wire mesh has gained increasing attention across global industrial markets due to its exceptional resistance to corrosion, high mechanical strength, and long service life in extreme environments. As industries face growing challenges related to material durability, safety, and operational efficiency, Monel wire mesh is emerging as a reliable solution for applications where conventional stainless steel or carbon steel materials may fail. Produced from Monel alloy, which is primarily composed of nickel and copper with small amounts of iron and other elements, this wire mesh combines the advantages of both metals, delivering stable performance under harsh chemical and marine conditions.

One of the most notable characteristics of Monel wire mesh is its outstanding corrosion resistance. The high nickel content allows the material to withstand exposure to seawater, salt spray, acids, alkalis, and a wide range of chemical media without significant degradation. This makes Monel wire mesh especially suitable for marine engineering, offshore platforms, shipbuilding, and coastal infrastructure, where constant contact with saltwater and humid air accelerates corrosion in ordinary metal materials. In chemical processing plants, Monel wire mesh is widely used for filtration, separation, and protection systems that must operate reliably in corrosive fluid environments.

In addition to corrosion resistance, Monel wire mesh offers excellent mechanical properties. It maintains high tensile strength and structural stability even at elevated temperatures, enabling its use in demanding thermal and pressure conditions. Compared with many alternative alloys, Monel demonstrates superior resistance to stress corrosion cracking and fatigue, which significantly reduces the risk of unexpected material failure. These properties make Monel wire mesh a preferred choice in oil and gas processing, power generation, and aerospace-related applications, where safety and reliability are critical.

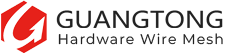

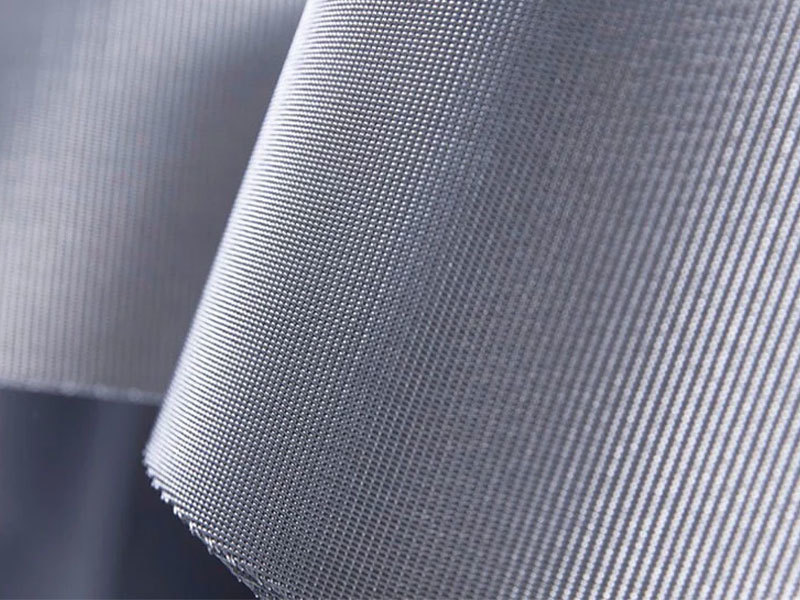

Manufacturing flexibility further enhances the value of Monel wire mesh. It can be produced in various wire diameters, mesh counts, and weaving patterns, including plain weave, twill weave, and Dutch weave, to meet specific filtration or screening requirements. This adaptability allows engineers to precisely control filtration accuracy, flow rate, and mechanical strength according to application needs. Whether used as a fine filter for chemical purification or as a robust protective mesh for industrial equipment, Monel wire mesh can be customized to deliver optimal performance.

The long service life of Monel wire mesh also contributes to its economic advantages. Although the initial cost of Monel alloy materials is higher than that of standard metals, the extended lifespan and reduced maintenance requirements often result in lower total ownership costs over time. In industries where equipment downtime leads to significant financial losses, the durability and reliability of Monel wire mesh provide substantial long-term value. As companies increasingly prioritize lifecycle cost analysis rather than upfront expenses, demand for Monel wire mesh continues to grow.

From a sustainability perspective, Monel wire mesh aligns with modern industrial goals of resource efficiency and waste reduction. Its resistance to corrosion and wear minimizes the frequency of replacement, reducing material consumption and waste generation. Furthermore, Monel alloys are recyclable, allowing valuable metals to be recovered and reused at the end of the product lifecycle. This supports environmentally responsible manufacturing practices and contributes to the development of more sustainable industrial supply chains.

Looking ahead, the market outlook for Monel wire mesh remains positive as global industries expand into more challenging operating environments. The growth of offshore energy projects, chemical processing facilities, and advanced manufacturing sectors is expected to further drive demand. Continuous improvements in alloy processing and wire mesh manufacturing technologies will likely enhance product consistency and performance, strengthening the position of Monel wire mesh as a high-performance material solution.

In conclusion, Monel wire mesh stands out as a critical material for industries that require exceptional corrosion resistance, mechanical strength, and long-term reliability. Its versatility, durability, and economic benefits make it an essential component in modern industrial systems. As industrial standards continue to rise, Monel wire mesh is set to play an increasingly important role in supporting safe, efficient, and sustainable operations worldwide.

TAG:

Related Posts

Information about applications of woven wire mesh