Stainless Steel Knitted Mesh Gains Wider Adoption in Industrial Sealing and Filtration Applications

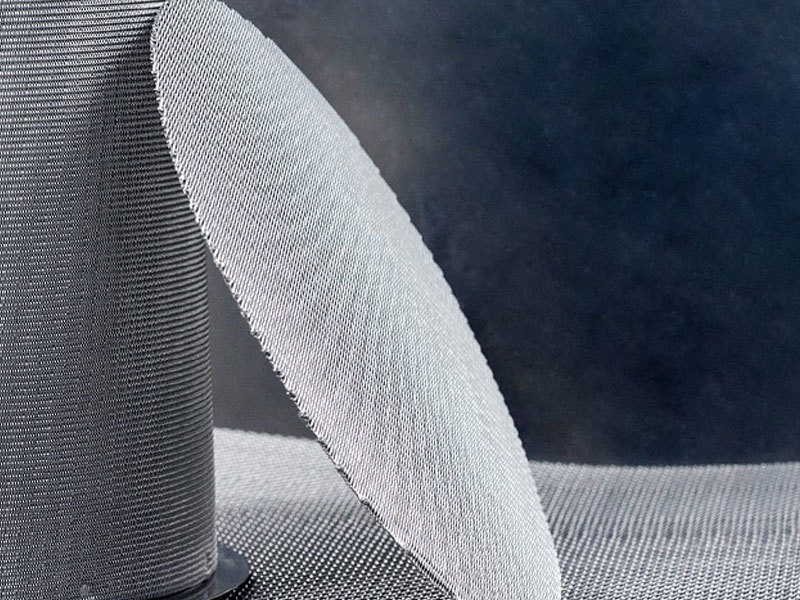

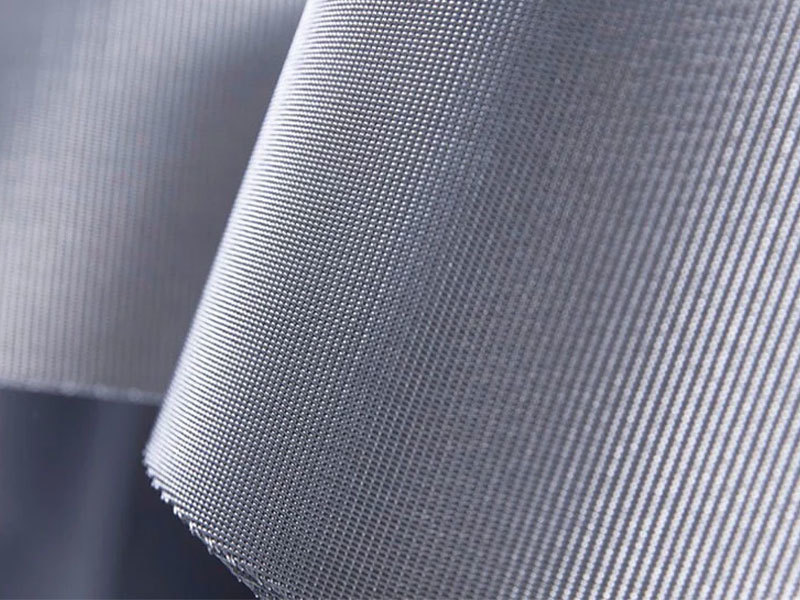

Stainless steel knitted mesh is increasingly recognized as a critical functional material across industrial sealing, filtration, and vibration control applications. Produced by knitting fine stainless steel wires into an interconnected loop structure, this type of mesh offers exceptional flexibility, elasticity, and mechanical resilience. Unlike traditional woven wire mesh, stainless steel knitted mesh can be compressed, shaped, and layered without losing its structural integrity, making it ideal for dynamic operating environments where movement, pressure fluctuation, or thermal expansion is common.

One of the primary advantages of stainless steel knitted mesh is its excellent performance under extreme conditions. Stainless steel provides strong resistance to corrosion, oxidation, and high temperatures, allowing the mesh to operate reliably in harsh chemical, marine, and high-temperature industrial settings. When used as a sealing or shielding material, the knitted structure enables effective absorption of vibration and noise while maintaining consistent contact pressure. This makes it widely applied in automotive exhaust systems, petrochemical equipment, power generation facilities, and heavy machinery where long-term stability and safety are essential.

In filtration and separation systems, stainless steel knitted mesh delivers high efficiency and durability. Its three-dimensional structure creates multiple flow paths that can capture particulates while allowing gases or liquids to pass through smoothly. The mesh can be customized by adjusting wire diameter, knitting density, and layering thickness to achieve specific filtration precision and flow resistance. Compared with disposable filter media, stainless steel knitted mesh offers reusability and long service life, reducing operational costs and supporting sustainable industrial practices.

Manufacturing advancements have further expanded the application range of stainless steel knitted mesh. Modern knitting equipment ensures uniform loop formation and consistent material performance across large production volumes. Post-processing techniques such as sintering, pressing, and forming allow the mesh to be converted into rings, pads, gaskets, and demisters tailored to different industrial needs. These value-added processes enhance product performance and make stainless steel knitted mesh a versatile solution for customized engineering applications.

As industries continue to pursue higher efficiency, reliability, and environmental responsibility, stainless steel knitted mesh is expected to see steady growth in global demand. Its combination of flexibility, strength, corrosion resistance, and reusability positions it as an essential material for modern industrial systems. With ongoing innovation in materials science and manufacturing technology, stainless steel knitted mesh will continue to play an important role in improving system performance and operational safety across a wide range of industrial sectors.

TAG:

Related Posts

Information about applications of woven wire mesh

No. 56, Weiyi Road, East of Economic Development Zone, Anping, Hebei, China.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.