Brass Wire Mesh Sees Growing Demand Across Industrial, Architectural, and Decorative Markets

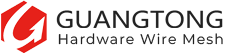

Brass wire mesh is experiencing renewed growth in global markets as industries increasingly seek materials that combine durability, corrosion resistance, and visual appeal. Manufactured from copper and zinc alloy wires, brass wire mesh offers a unique balance of mechanical strength and aesthetic quality, making it suitable for a wide range of applications. From industrial filtration and screening to architectural decoration and interior design, brass wire mesh continues to expand its role as both a functional and decorative material.

In industrial applications, brass wire mesh is widely used for filtration, separation, and screening processes. Its excellent resistance to corrosion, especially in mildly acidic or alkaline environments, makes it ideal for use in chemical processing, water treatment, and food-related industries. Brass wire mesh maintains stable performance under continuous operation, ensuring reliable filtration accuracy and long service life. Compared with steel-based meshes, brass wire mesh offers improved resistance to rust while retaining sufficient strength for medium-load applications. This balance of performance and durability contributes to lower maintenance costs and improved operational efficiency for industrial users.

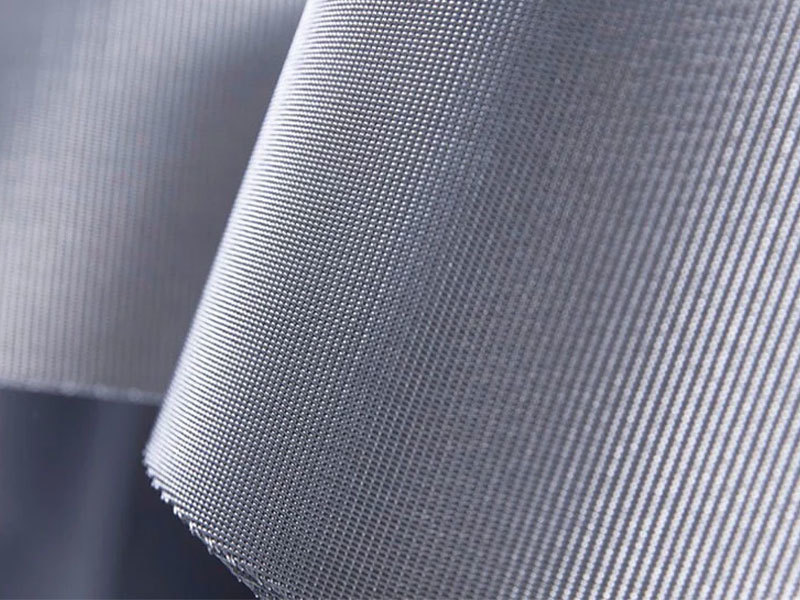

Beyond industrial use, brass wire mesh has gained popularity in architectural and interior design projects. Its warm golden tone and refined texture allow it to function as both a structural and decorative element. Designers frequently incorporate brass wire mesh into building facades, partitions, ceilings, railings, and ventilation panels to achieve a modern yet timeless aesthetic. The material’s ability to be woven into various patterns and mesh sizes provides designers with flexibility to control transparency, light diffusion, and airflow while maintaining a cohesive visual identity. As architectural trends continue to emphasize natural materials and metallic finishes, brass wire mesh has become a preferred choice for high-end commercial and residential spaces.

Technological advancements in wire drawing and weaving processes have significantly improved the quality and consistency of brass wire mesh products. Modern manufacturing techniques allow precise control of wire diameter, mesh opening, and surface finish, ensuring uniformity and reliability across large production volumes. Surface treatments such as polishing, oxidation control, and protective coatings further enhance the mesh’s appearance and resistance to environmental factors. These improvements have expanded the application range of brass wire mesh and increased its competitiveness in both traditional and emerging markets.

Sustainability considerations are also contributing to the growing appeal of brass wire mesh. Brass is a recyclable material, and its reuse supports resource efficiency and environmental responsibility. Many manufacturers now emphasize recyclable sourcing and optimized production processes to reduce waste and energy consumption. As industries and designers place greater emphasis on sustainable materials, brass wire mesh aligns well with green building standards and environmentally conscious manufacturing practices.

Market analysts note that demand for brass wire mesh is expected to continue rising, driven by growth in construction, renovation, industrial upgrading, and customized design solutions. Its versatility allows it to bridge the gap between engineering performance and decorative value, making it suitable for both functional and aesthetic applications. With ongoing innovation in manufacturing technology and expanding use cases, brass wire mesh is set to remain a valuable material across multiple industries, offering long-term reliability, visual sophistication, and sustainable performance.

TAG:

Related Posts

Information about applications of woven wire mesh