Stainless Steel Filter Mesh: Precision Filtration and Industrial Versatility

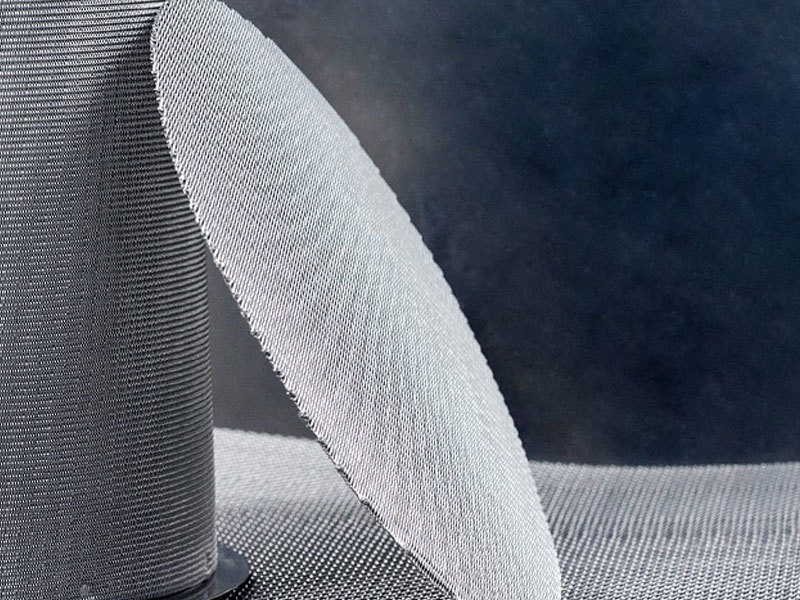

Stainless steel filter mesh is an essential material widely used across multiple industries for precise filtration, separation, and protective applications. Made from high-quality stainless steel wires woven into a consistent mesh pattern, it offers durability, corrosion resistance, and high tensile strength. These features make stainless steel filter mesh a preferred choice in environments that require long-lasting performance under demanding conditions, including chemical processing, food and beverage production, pharmaceuticals, petrochemicals, water treatment, and environmental engineering.

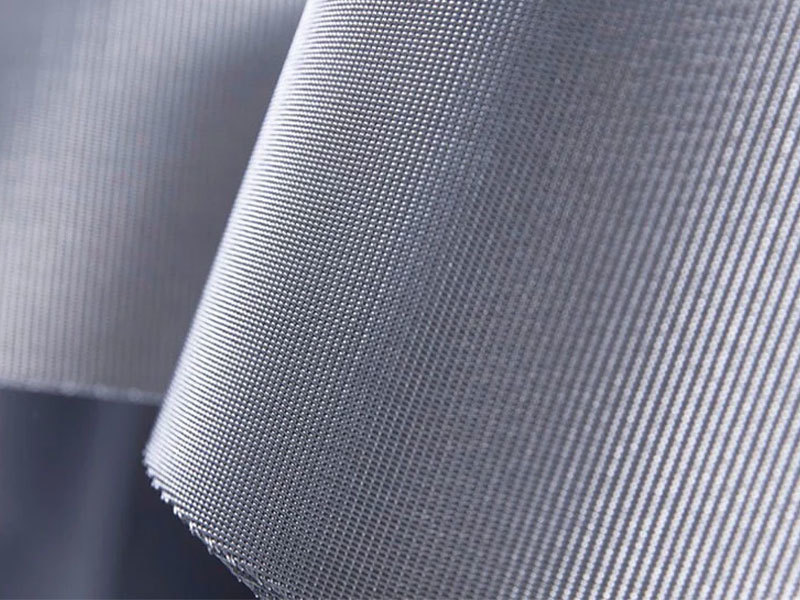

The unique construction of stainless steel filter mesh allows it to handle fine particle filtration while maintaining structural integrity. Its precise openings ensure consistent filtration, separating liquids, gases, or solid particles efficiently. Depending on the weave type, wire diameter, and mesh size, stainless steel filter mesh can be customized to meet specific industrial requirements. Common weave types include plain weave, twill weave, and Dutch weave, each offering different advantages in terms of strength, flow rate, and filtration precision.

One of the major advantages of stainless steel filter mesh is its resistance to corrosion and chemical damage. Unlike other materials, stainless steel maintains its structural and aesthetic integrity even when exposed to acidic, alkaline, or chemically aggressive environments. This feature makes it particularly suitable for chemical processing plants, food processing facilities, and water treatment operations where exposure to corrosive liquids is frequent. High-grade stainless steel such as 304, 316, and 316L is commonly used to enhance resistance and longevity.

Durability and strength are other key benefits of stainless steel filter mesh. The woven wires provide both flexibility and mechanical stability, ensuring that the mesh maintains its shape even under high pressure, abrasive materials, or continuous use. This makes stainless steel filter mesh ideal for industrial filtration systems, including oil refining, gas filtration, pharmaceutical production, and slurry separation. It can also withstand repeated cleaning and sterilization without significant wear, making it highly suitable for food and medical applications.

Stainless steel filter mesh is also highly versatile and customizable. Wire diameters can range from microns to millimeters, while mesh counts can vary widely depending on application requirements. This allows manufacturers to produce filter mesh tailored to specific particle sizes or flow rates. Additionally, mesh panels can be cut, welded, or framed to fit industrial equipment, ensuring seamless integration into filtration systems. This flexibility has made stainless steel filter mesh a standard in industrial and engineering design.

Environmental sustainability is increasingly important in the selection of filtration materials. Stainless steel filter mesh is fully recyclable and has a long service life, reducing the need for frequent replacements and minimizing waste. Its durability ensures lower maintenance and operational costs, contributing to energy efficiency and sustainable industrial practices. By choosing stainless steel filter mesh, industries can meet filtration needs while maintaining environmentally responsible operations.

Apart from industrial filtration, stainless steel mesh also finds applications in architectural, safety, and decorative contexts. In construction, it can serve as protective barriers, insect screens, or reinforcement panels. In architectural design, stainless steel mesh provides a modern, durable material for facades, partitions, and decorative features. The combination of aesthetics, durability, and strength makes it suitable for both functional and visual applications, further expanding its versatility.

In addition, stainless steel filter mesh is often used in precision laboratory and research applications. Its consistent mesh openings allow for controlled experiments involving liquid and gas filtration, particle separation, and even microfiltration. The hygienic properties of stainless steel, combined with its chemical and heat resistance, ensure that laboratory results remain accurate and uncontaminated.

In conclusion, stainless steel filter mesh is a durable, versatile, and high-performance material that plays a critical role in industrial, architectural, and laboratory applications. Its precise filtration capabilities, resistance to corrosion, and mechanical strength make it indispensable in industries ranging from chemical processing and pharmaceuticals to water treatment, food production, and construction. With customizable sizes, weaves, and configurations, stainless steel filter mesh meets the growing demands for reliable, efficient, and sustainable filtration solutions. Its combination of strength, longevity, and adaptability ensures that it will remain a cornerstone material for filtration and industrial processes in the foreseeable future.

TAG:

Related Posts

Information about applications of woven wire mesh