Dutch Woven Wire Mesh: Precision, Durability, and Versatile Industrial Applications

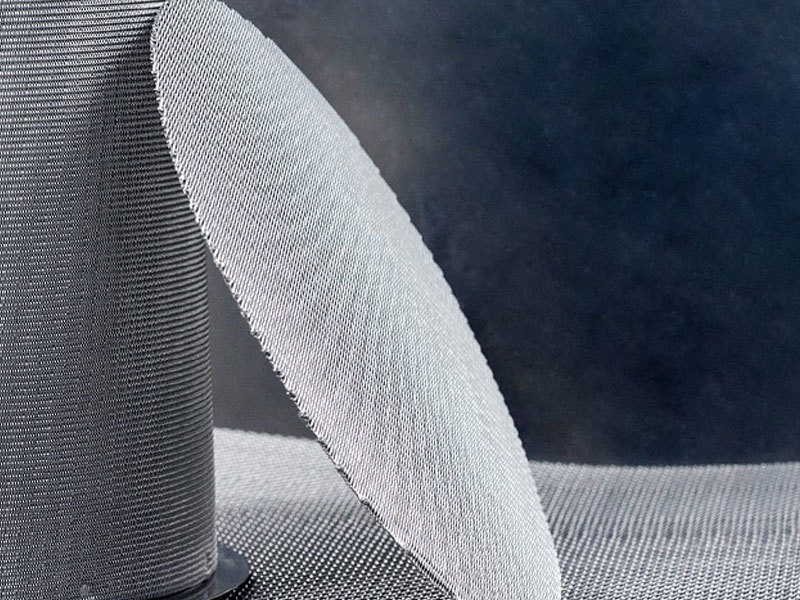

Dutch woven wire mesh, often referred to as “Dutch weave,” is a high-precision, durable mesh product widely used in filtration, separation, and screening applications across multiple industries. Renowned for its tight weave, superior strength, and dimensional stability, Dutch woven wire mesh is designed to handle demanding environments where precision and reliability are essential. It is crafted by weaving fine wires over and under thicker support wires, creating a mesh with excellent resistance to wear, corrosion, and pressure.

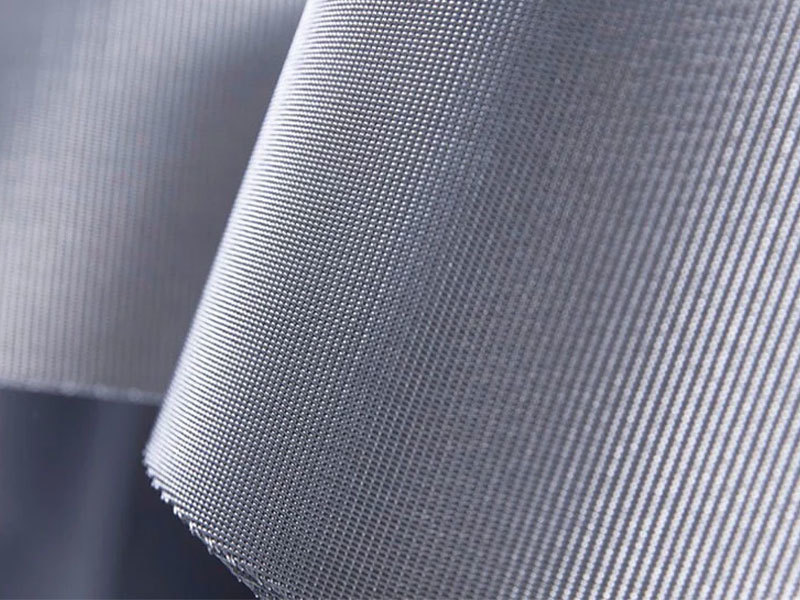

The unique construction of Dutch woven wire mesh allows it to achieve very small openings while maintaining high tensile strength. This makes it ideal for applications requiring precise particle separation, liquid filtration, and gas or air purification. Industries such as chemical processing, pharmaceuticals, food and beverage, petrochemical, mining, and environmental engineering rely on Dutch woven wire mesh to ensure product quality and operational efficiency. Its robustness allows it to withstand high temperatures, abrasive materials, and continuous operation without significant deformation.

One of the primary advantages of Dutch woven wire mesh is its precision filtration capability. The combination of fine wires and strong support wires ensures uniform mesh openings, enabling consistent separation of particles and fluids. This precision is critical in industries like pharmaceuticals, where exact particle size separation can impact product quality, or in chemical processing, where impurities must be removed to maintain process integrity. Additionally, Dutch woven wire mesh can be produced in a variety of weave patterns and materials, including stainless steel, galvanized steel, and specialized alloys, offering resistance to corrosion, acids, and high temperatures.

Durability and strength are inherent features of Dutch woven wire mesh. The thicker support wires provide structural stability, while the fine wires create the filtration surface. This dual-wire construction ensures the mesh maintains its shape under mechanical stress, pressure, or repeated cleaning cycles. The combination of strength and flexibility makes it suitable for use in sieves, strainers, filters, and protective screens. Furthermore, Dutch woven wire mesh is often used in high-pressure filtration systems, such as oil refining, chemical reactors, and water treatment plants, where its resistance to deformation and clogging contributes to operational reliability.

Customizability is another important feature of Dutch woven wire mesh. Manufacturers can adjust wire diameter, mesh count, and weave pattern to meet specific application requirements. For instance, tighter weaves with finer wires are used for microfiltration or precision sieving, while coarser weaves with thicker wires are suitable for bulk material screening or heavy-duty filtration. The mesh can also be cut, welded, or framed according to the needs of industrial equipment, ensuring easy integration into existing systems and machinery.

Environmental and industrial sustainability considerations also play a role in Dutch woven wire mesh production. Many manufacturers use corrosion-resistant stainless steel or recyclable alloys to reduce environmental impact. Long service life and resistance to wear mean fewer replacements, reducing waste and operational downtime. Its robust design minimizes the need for frequent maintenance, contributing to energy efficiency and cost savings in industrial processes.

In addition to industrial applications, Dutch woven wire mesh has specialized uses in architectural, construction, and safety applications. It can be used as decorative panels, protective barriers, or security screens due to its strength, precision, and customizable design. In construction, Dutch woven wire mesh is applied for reinforcement, screening aggregates, or controlling erosion, demonstrating its versatility beyond industrial filtration.

In conclusion, Dutch woven wire mesh represents a combination of precision engineering, durability, and versatility, making it a critical component across a wide range of industrial, environmental, and architectural applications. Its unique weave structure, high tensile strength, and resistance to wear and corrosion ensure consistent performance in challenging environments. From chemical processing and pharmaceuticals to food production, mining, and construction, Dutch woven wire mesh delivers reliable filtration, separation, and structural support. As industries continue to demand high-quality, efficient, and long-lasting materials, Dutch woven wire mesh remains a preferred solution for both precision and durability, providing exceptional value and operational reliability.

TAG:

Related Posts

Information about applications of woven wire mesh